Asset Inspection

MMC asset inspection solution revolutionizes mining equipment maintenance through non-contact aerial inspections. Our drones capture high-resolution visual and thermal imagery of crushers, conveyors, and processing plants while operations continue.

Painpoints

- – Manual inspections are time-consuming and inefficient, especially across large mining sites.

- – Conventional inspection methods typically require significant manpower and resources.

- – Low inspection frequency might lead to increased operational cost and equipment failures.

- – Mining assets in hard-to-reach locations present challenges for traditional inspection methods.

Advantages

- Easily evaluate assets status, significantly streamlining data collection process.

- Reduce cost and improve efficiency with easy-to-deploy aerial data collection solutions.

- Collect real-time data, enabling mining operations to respond quickly to changing situations.

- Aerial perspective allows you to view assets located difficult areas, offering a more comprehensive inspection.

Solution

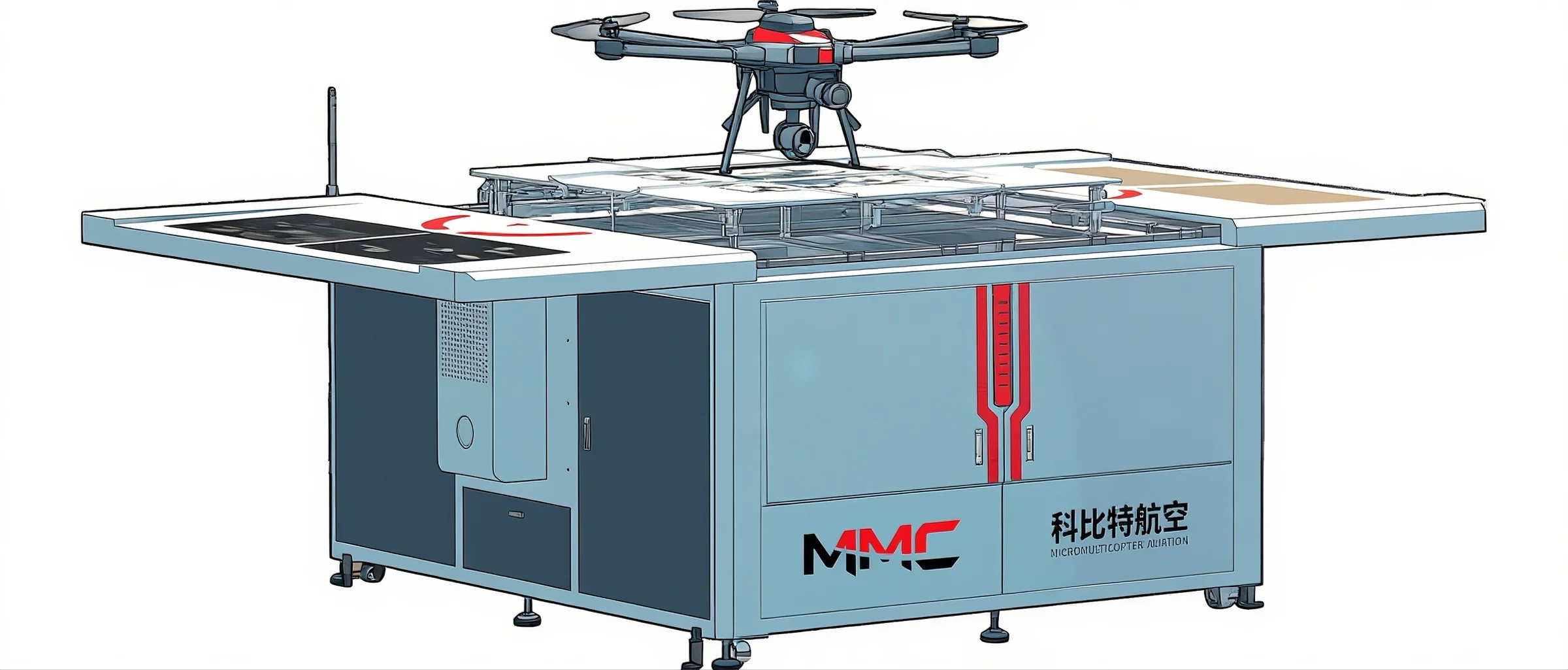

Automated Remote Asset Inspection Solution

Skylle Ⅱ Hangar + MMC X4 Pro: Automated remote asset inspection solution for mining with full automation, high-accuracy mapping, rugged reliability.

- Fully automated missions: Pre-programmed routes, autonomous takeoff/landing, zero human oversight for consistent asset inspection.

- Cost savings: Minimizes labor by 70%, automates battery swaps/maintenance, slashes time and costs.

- High-accuracy mapping: MMC X4 Pro’s 5-lens camera captures sub-centimeter precision data for detailed asset inspection.

- Rugged & easy deployment: Withstands -20°C~65°C, IP54 protection, tool-free maintenance for extreme mining environments.

Drone Platform

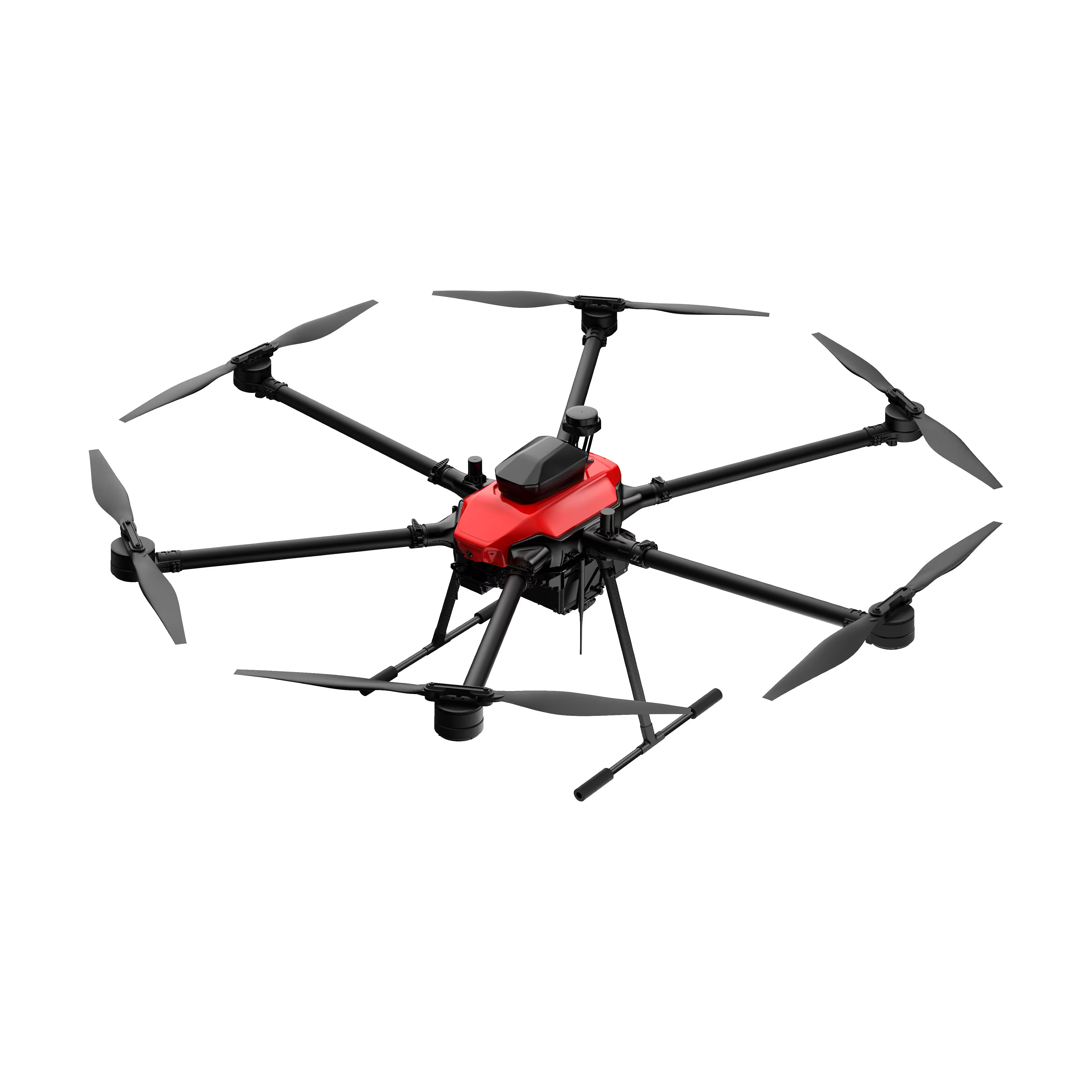

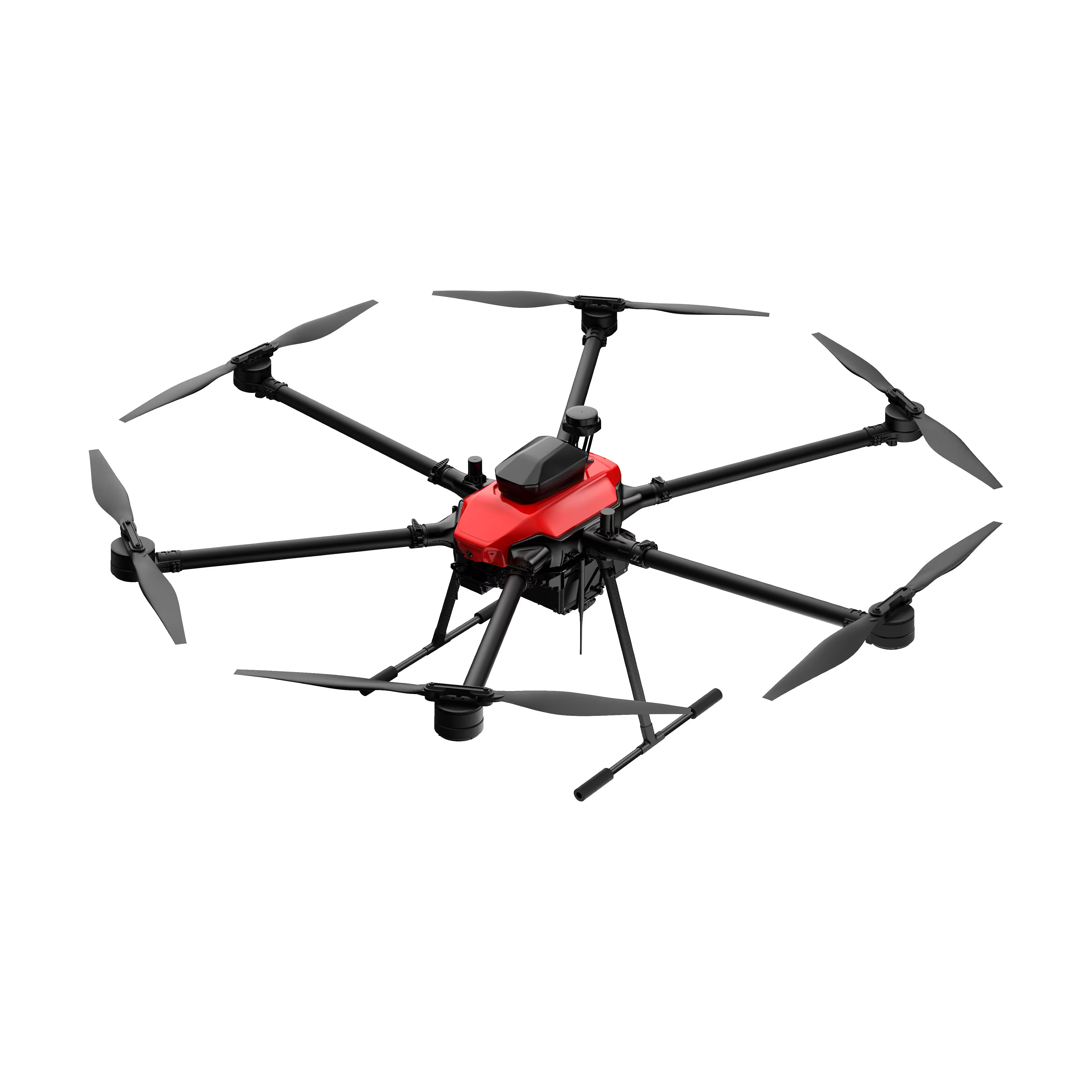

Skylle Ⅱ

Hexacopter Industrial Heavy-Lift Drone - 10kg Payload | 60min Flight Time | RTK cm-Level Positioning | IP54 Rated Read More

Learn MorePayload And Software

X4 Pro

MMC X4 Pro is a high-performance, multi-purpose aerial survey camera designed for 3D modeling and precision mapping. As a professional five-lens oblique photography system, it breaks through the limitations of traditional single-angle mapping cameras, providing an integrated, high-precision, and efficient aerial survey solution for various mapping scenarios. Read More

Learn MoreSkylle Ⅱ + MMC X4 Pro: Redefining Mining Asset Inspection with Automated Remote Precision

In mining, asset inspection is the backbone of operational safety, efficiency, and compliance—but traditional manual drone operations are slow, labor-intensive, and prone to human error. Enter the Skylle Ⅱ Hangar Edition + MMC X4 Pro Automated Remote Asset Inspection Solution—paired with Skylle Ⅱ’s dedicated hangar, this integrated system transforms asset inspection into a seamless, 24/7 process that delivers consistent data, cuts costs, and thrives in mining’s harshest environments.

Why Skylle Ⅱ + MMC X4 Pro?

1. Fully Automated Missions: Consistent Asset Inspection, Zero Human Oversight

Skylle Ⅱ’s dedicated hangar and drone work in tandem to automate every step: pre-programmed flight routes, autonomous takeoff/landing, and automatic data uploads. No need for on-site operators—set it and forget it. Whether inspecting conveyor belts, stockpiles, or infrastructure, the system ensures regular, repeatable data collection, eliminating gaps in monitoring and reducing reliance on manual scheduling.

2. Cost Savings: Slash Labor & Time

Manual drone operations demand skilled pilots, travel time, and on-site coordination—costs that add up fast. Skylle Ⅱ + MMC X4 Pro minimizes labor needs by 70%: the hangar handles battery swaps, maintenance alerts, and mission rescheduling automatically. With faster data turnaround and fewer human hours, mining teams see substantial cost savings while scaling coverage across remote or hard-to-reach sites.

3. High-Accuracy Mapping: MMC X4 Pro Captures Details That Matter

At the core of this solution is the MMC X4 Pro’s 5-lens high-resolution mapping camera, engineered for precision inspection. Its multi-angle imaging captures 3D terrain data, structural deformities, and equipment wear with sub-centimeter accuracy. Whether measuring stockpile volumes or detecting cracks in high-wall structures, the X4 Pro turns raw images into actionable insights—critical for proactive inspection and maintenance.

4. Rugged Reliability: Asset Inspection Thrives in Extreme Mining Environments

Mining sites don’t wait for perfect weather—and neither does this solution. Skylle Ⅱ’s dedicated hangar boasts IP54 protection, withstanding heavy rain, dust, and temperatures from -20°C to 65°C. High-altitude stable flight and wind resistance up to 12m/s ensure uninterrupted asset inspection, even in remote mountainous or desert mining regions. Plus, tool-free maintenance and remote diagnostics make deployment and upkeep a breeze.

Elevate Your Asset Inspection Today

Skylle Ⅱ + MMC X4 Pro isn’t just a tool—it’s a paradigm shift for mining asset inspection. By combining automation, cost efficiency, precision, and ruggedness, it empowers teams to focus on decision-making, not data collection.

Ready to Transform Asset Inspection?

Contact us to see how Skylle Ⅱ + MMC X4 Pro redefines mining asset inspection—consistent, cost-effective, and built to conquer the toughest sites.

Skylle Ⅱ Hangar | MMC X4 Pro | Automated Asset Inspection for Mining’s Next Level.

Robust Visual & Thermal Inspection Solution

Skylle Ⅱ + MMC HT18R: Robust visual & thermal mining solution with 55min flight, multi-sensor payload, real-time collaboration for asset inspection.

- Reliable multi-purposed drone: Skylle Ⅱ resists harsh environments, ensuring stable asset inspection in mining sites.

- MMC HT18R payload: Dual-visual, thermal sensors & laser rangefinder for precise, multi-dimensional inspection data.

- 55min flight time: Extended endurance boosts field efficiency, covering more areas per asset inspection mission.

- Real-time collaboration: Livestream missions or upload data to MMC, enabling seamless cross-team asset inspection teamwork.

Drone Platform

Skylle Ⅱ

Hexacopter Industrial Heavy-Lift Drone - 10kg Payload | 60min Flight Time | RTK cm-Level Positioning | IP54 Rated Read More

Learn MorePayload And Software

HT18R

Industrial-Grade 4-Sensor Payload Redefining Precision Inspection HT18R Find More Why Choose MMC HT18R? Multi-Sensor Integration Combines 48MP wide-angle/telephoto visible cameras, 640×512 thermal imager, and 2000m laser rangefinder, enabling comprehensive day-night observation and data collection in one payload. Read More

Learn MoreSkylle Ⅱ + MMC HT18R: Elevate Mining Asset Inspection with Robust Visual & Thermal Precision

Mining operations demand inspections that cut through harsh environments, deliver actionable data, and keep teams safe—without sacrificing speed or accuracy. Enter the Robust Visual & Thermal Inspection Solution: pairing the reliable Skylle Ⅱ drone platform with the advanced MMC HT18R payload, designed to transform how mining sites conduct asset inspection.

A Drone Platform Built for Reliability

Skylle Ⅱ stands as a rugged, multi-purposed workhorse, engineered to thrive where mining operations happen. Its robust airframe resists high winds, dust, and temperature extremes, ensuring stable flight even in remote, challenging sites—critical for consistent asset inspection.

MMC HT18R: Sensor Powerhouse for Precision

At the heart of this solution is the MMC HT18R payload, a sensor powerhouse built for precision. Equipped with dual 48MP visual cameras (wide-angle + telephoto), a 640×512 thermal imager, and a 2000m laser rangefinder, it captures sharp 6K visuals by day and clear thermal data by night, turning raw data into actionable insights that drive proactive asset inspection.

Fly Longer, Inspect More

Time is money in mining, and Skylle Ⅱ maximizes every minute with 55 minutes of flight time. Cover more ground in a single mission: scan conveyor belts, survey stockpiles, or monitor high-risk areas without frequent battery swaps. This extended endurance boosts field-work efficiency, letting your team complete more tasks in less time—no more cutting missions short when asset inspection matters most.

Livestream & Collaborate Seamlessly

Inspection data shouldn’t stay siloed. Skylle Ⅱ + MMC HT18R lets you livestream missions directly to your team, so experts can guide inspections remotely or flag issues on the spot. Post-mission, upload data to MMC’s cloud platform for seamless cross-team collaboration—share 3D models, thermal reports, or visual logs with engineers, managers, or maintenance crews, ensuring everyone works from the same, up-to-date insights.

Elevate Your Mining Inspections Today

In mining, the difference between a minor issue and a major incident often lies in how well you see—and act on—critical details. Skylle Ⅱ + MMC HT18R doesn’t just inspect; it empowers your team with clarity, efficiency, and confidence, even in the harshest conditions.

Ready to Transform How You Monitor Your Site?

Skylle Ⅱ + MMC HT18R: Where robust performance meets intelligent sensing—for mining asset inspection that keeps pace with your operation.

Skylle Ⅱ Drone | MMC HT18R Payload | Visual & Thermal Precision for Mining’s Frontlines.