Site Safety

MMC Drones enhances mining safety with automated aerial inspections. Our solutions capture high-resolution site data to detect hazards, monitor equipment, and track personnel in real-time. Drones reduce inspection risks by 90% versus manual methods while cutting survey time by 75%.

Painpoints

- – Mining areas ofen have inaccessible or high-risk zones, posing challenges for personnel safety.

- – Obtaining timely and accurate information for swift responses can be difficult.

- – Manual inspections might overlook hidden hazards, and data collection might not be comprehensive or accurate.

Advantages

- Improve mine operational safety and reduce risk with frequent aerial oversight.

- Enhance decision-making processes with real-time imagery from the mine operations.

- Create high-precision 2D and 3D models for accurate risk identification and assesment.

Solution

Automated Routine Mining Site Monitoring Solution

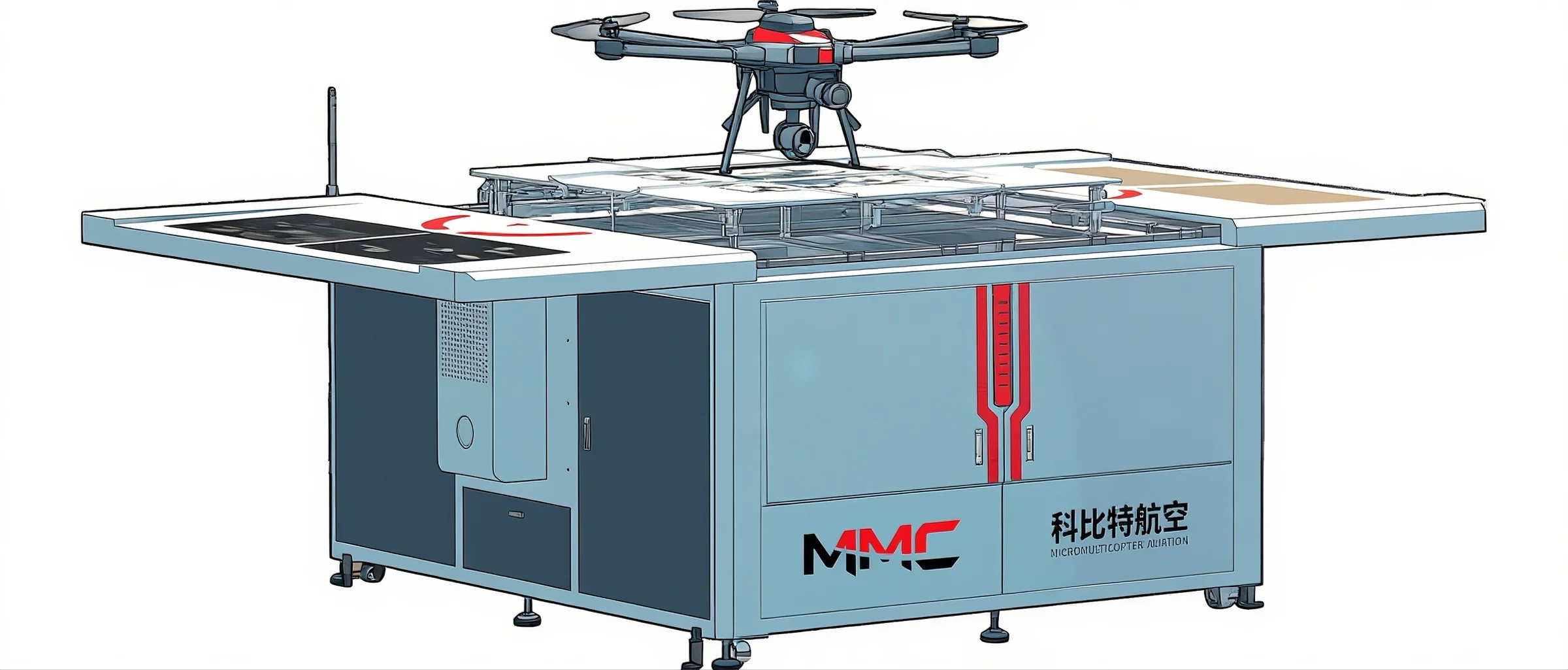

Notuzi Ⅲ Hangar + MMC HT10RW: Automated routine mining site monitoring solution ensuring site safety via auto flights, hazard detection, real-time data.

- Automated scheduled flights: Consistent site safety inspections without manual operation, ensuring frequent monitoring.

- Labor/time minimized: Significant cost savings for site safety vs traditional manual drone operations.

- Hazard identification: Detects overheated machinery, structural weaknesses to protect site safety proactively.

- Real-time data: Enables immediate analysis/decision-making via live transmission, safeguarding site safety instantly.

Drone Platform

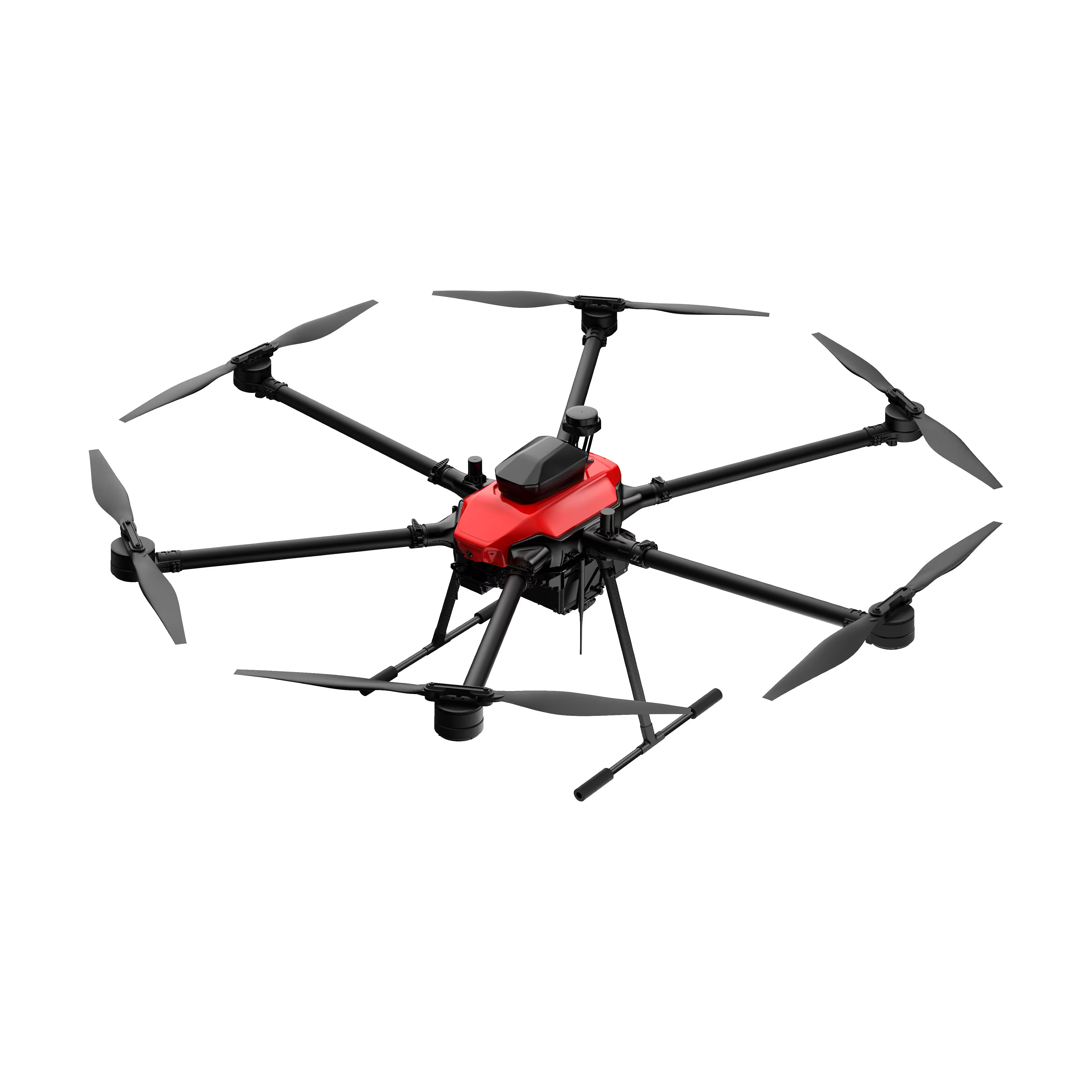

Skylle Ⅱ

Hexacopter Industrial Heavy-Lift Drone - 10kg Payload | 60min Flight Time | RTK cm-Level Positioning | IP54 Rated Read More

Learn MorePayload And Software

HT10RW

A compact 4-in-1 camera payload (380g) designed for industrial drones, integrating multi-sensor capabilities to meet diverse mission requirements across day/night and complex environments. It is widely applicable in power inspection, oil pipeline monitoring, photovoltaic inspection, urban fire rescue, and forest fire prevention. Read More

Learn MoreAutomated Routine Mining Site Monitoring: Notuzi Ⅲ + MMC HT10RW – Elevate Site Safety, 24/7

In mining, site safety isn’t just a priority—it’s the foundation of every operation. Yet traditional safety checks, reliant on manual patrols or sporadic drone flights, often leave gaps, risking missed hazards and delayed responses. Enter the Automated Routine Mining Site Monitoring Solution: pairing Notuzi Ⅲ (Hangar Edition) with MMC HT10RW payload and its dedicated hangar, this system transforms safety into a proactive, 24/7 process that never sleeps.

Automated Flights: Consistent Safety, No Manual Effort

Notuzi Ⅲ’s dedicated hangar and drone work in harmony to automate every step of safety monitoring. Pre-scheduled flight routes—daily, hourly, or on-demand—ensure frequent, consistent inspections of haul roads, stockpiles, and infrastructure. No need for on-site operators: the system handles takeoff, landing, and battery swaps automatically, guaranteeing safety checks happen when needed, not just when staff are available.

Cost Savings: More Safety, Less Labor

Manual drone operations demand skilled pilots, travel time, and coordination—costs that drain resources better spent on safety. Notuzi Ⅲ slashes labor needs by 80%: its hangar self-manages maintenance, mission rescheduling, and data uploads. With fewer hours spent on logistics, teams redirect focus to critical safety tasks, turning cost savings into safer, more efficient operations.

Hazard Detection: Spot Risks Before They Threaten Safety

At the core of this solution is the MMC HT10RW payload, engineered to uncover hidden threats to safety. Equipped with thermal imaging, high-resolution visual sensors, and AI-powered analytics, it identifies overheated machinery bearings, cracks in high-wall structures, or unauthorized personnel in restricted zones—all in real time. By flagging potential dangers early, the system prevents accidents and protects safety before incidents occur.

Real-Time Data: Decisions That Safeguard Safety Instantly

Site safety can’t wait for delayed reports. Notuzi Ⅲ streams live data to your team’s dashboard, delivering thermal scans, structural images, and hazard alerts directly to decision-makers. Whether it’s rerouting a haul truck from a unstable slope or shutting down overheated equipment, real-time insights enable immediate action—turning “what if” into “we fixed it,” and keeping safety at the forefront of every choice.

Why Notuzi Ⅲ + MMC HT10RW? Site Safety, Redefined

Mining sites are dynamic, and safety demands a solution that adapts. Notuzi Ⅲ’s rugged hangar thrives in extreme conditions—dust, rain, and temperatures from -20°C to 60°C—ensuring safety monitoring never pauses. Paired with MMC HT10RW’s precision, this system doesn’t just check boxes; it builds a culture of proactive safety, where every hazard is spotted, every risk is mitigated, and every team member goes home safe.

10x Site Safety, Zero Compromise

From automated flights to real-time alerts, Notuzi Ⅲ + MMC HT10RW isn’t just a tool—it’s a commitment to site safety. It’s the difference between reactive responses and preventive action, between missed hazards and 24/7 vigilance. For mining operations ready to prioritize site safety, this solution delivers: consistency, efficiency, and peace of mind—proving that when it comes to site safety, automation isn’t the future. It’s now.

Ready to Transform Site Safety?

Contact us today to see how Notuzi Ⅲ + MMC HT10RW makes site safety non-negotiable—for your team, your operation, and your bottom line.

Notuzi Ⅲ Hangar Edition | MMC HT10RW | Automated Site Safety, Always On.