Electricity

MMC electricity inspection solution streamlines the management of electrical grids, substations, and power plants through advanced aerial monitoring. Drones efficiently perform construction oversight, routine inspections, and maintenance checks while reducing human risk and downtime. With high-resolution imaging and thermal sensing, the solution ensures accurate fault detection and supports safe, cost-effective energy infrastructure operations.

MMC Drone Solutions for Electricity

Powerline Inspection

MMC powerline inspection solution enhances the reliability of transmission and distribution systems by enabling automated, routine drone inspections. These drones can identify early signs of wear or damage—such as overheating in clamps or switches—through high-resolution thermal imaging.

Substation Inspection

MMC substation inspection solution ensures the reliability and stability of substations and converter stations through efficient aerial inspections. Using high-resolution visual and infrared imaging, drones capture detailed views of electrical components and generate accurate digital models of infrastructure.

Traditional Challenges for Powerline Inspection

- Traditional inspection methods are costly and time-consuming due to the distance of transmission lines.

- The complexity of the infrastructure, with numerous inspection points, results in a high manual inspection workload and difficulties in ensuring consistent quality.

- Maintaining inspection records is difficult, as manual inspections cannot be easily digitized, archived, or traced.

- Environmental factors can render some areas inaccessible or hazardous, posing risks to inspection personnel.

How Drones Aid Powerline Inspection

- Extend operating range, frequency, and efficiency with long-distance and automated drone inspections.

- Enhance inspection quality with close-range, accurate, and repeatable data capture processes.

- Easily store and manage drone imagery and digital models to monitor changes and prevent failures.

- Ensure personnel safety while maintaining high inspection quality using aerial visual and thermal imagery of critical components.

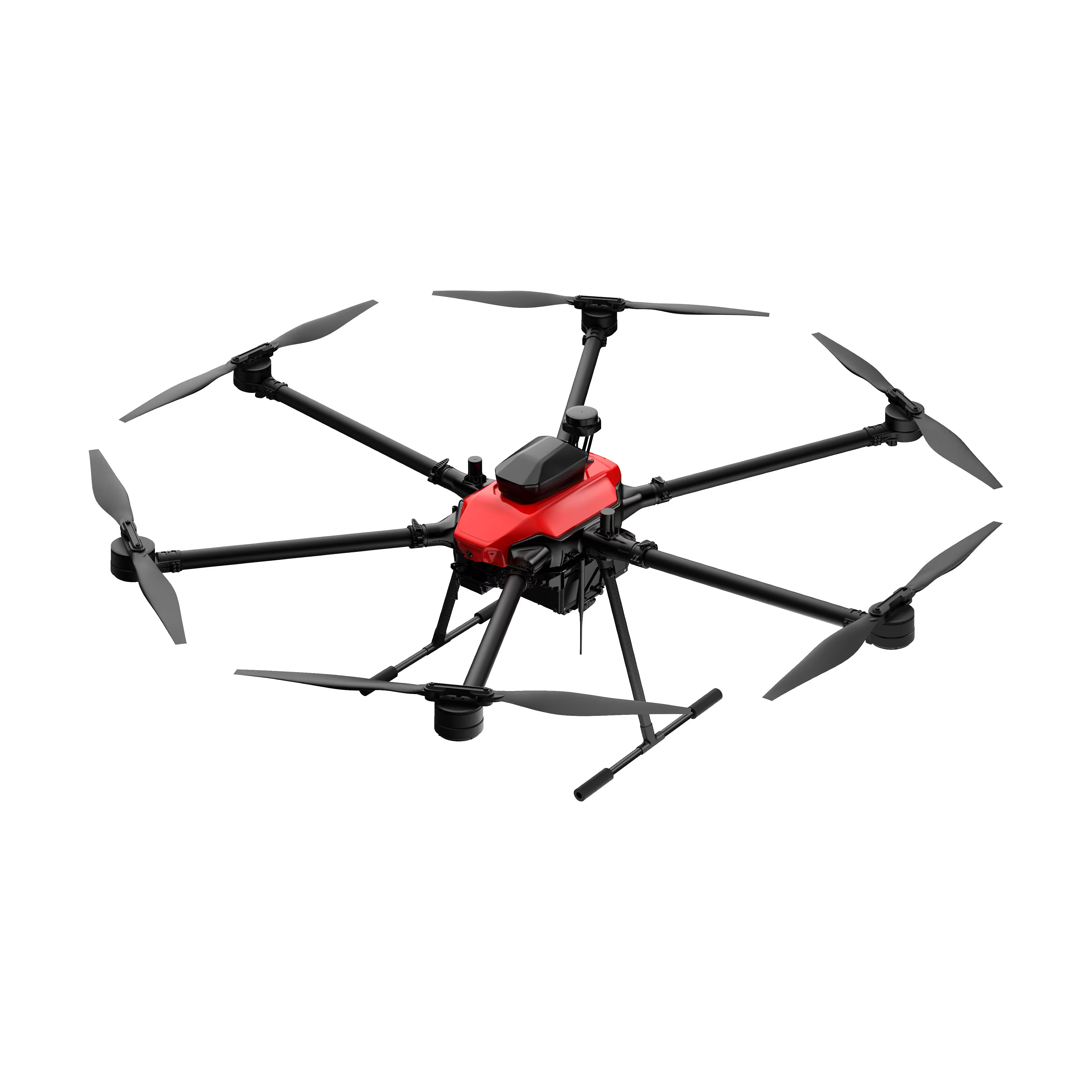

Related Products

Traditional Challenges for Substation Inspection

- Manual inspections are labor-intensive and involve navigating complex structures, with evaluations largely based on the subjective assessments of inspectors.

- High-voltage equipment necessitates strict adherence to safety clearances, which restricts the accessibility of inspection personnel to certain zones and apparatuses.

- The inspection of vital components such as transformers, circuit breakers, and busbars is often hindered by limited visibility, complicating the task of achieving a comprehensive inspection and posing difficulties in the efficient management of inspection data.

How Drones Aid Substation Inspection

- Automated inspection protocols reduce the necessity for hands-on involvement and decrease the duration spent on-site, thereby enhancing efficiency and quality.

- Drones are capable of approaching electrical equipment closely or utilizing high-resolution zoom lenses to obtain sharp, intricate visuals.

- Aerial inspections offer novel vantage points for inspecting critical components and facilitate the assessment of equipment condition through advanced thermal imaging analysis.