Substation Inspection

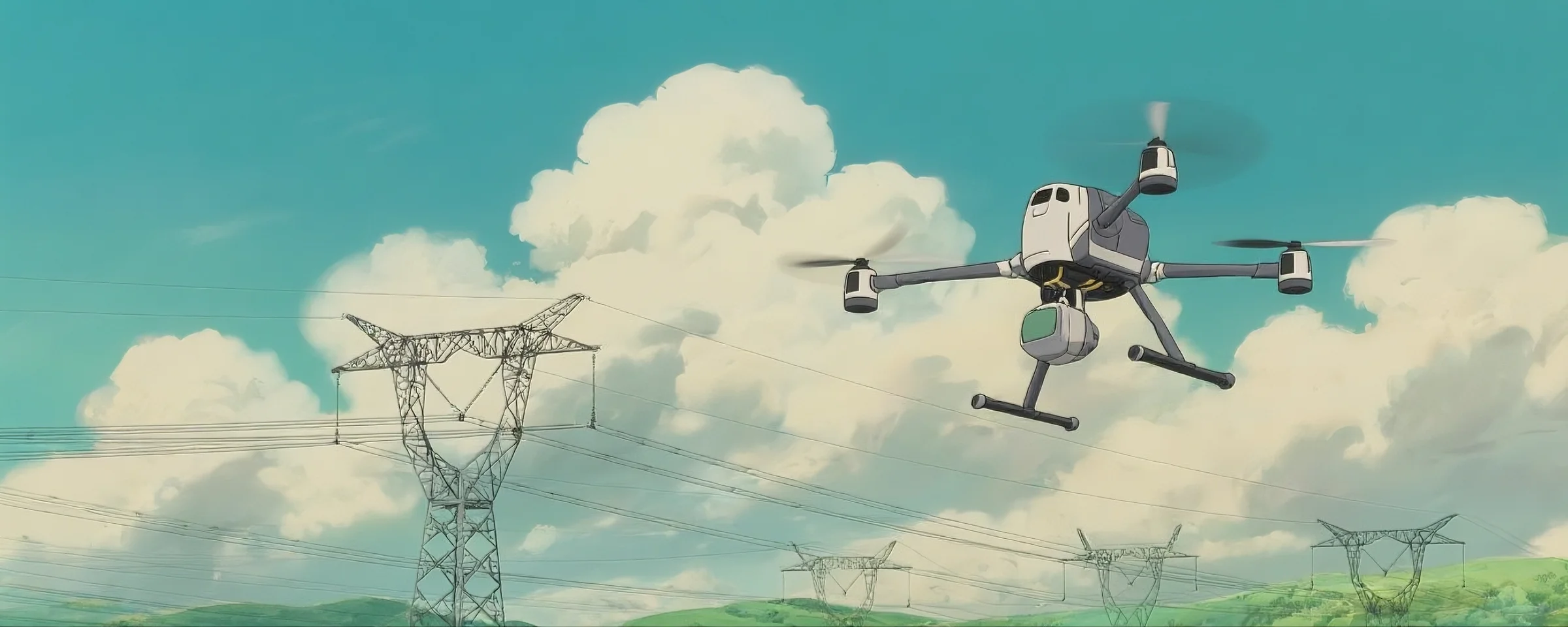

MMC substation inspection solution ensures the reliability and stability of substations and converter stations through efficient aerial inspections. Using high-resolution visual and infrared imaging, drones capture detailed views of electrical components and generate accurate digital models of infrastructure. This enables early fault detection, enhances maintenance precision, and supports uninterrupted grid performance.

Painpoints

- – Manual inspections are labor-intensive and involve navigating complex structures, with evaluations largely based on the subjective assessments of inspectors.

- – High-voltage equipment necessitates strict adherence to safety clearances, which restricts the accessibility of inspection personnel to certain zones and apparatuses.

- – The inspection of vital components such as transformers, circuit breakers, and busbars is often hindered by limited visibility, complicating the task of achieving a comprehensive inspection and posing difficulties in the efficient management of inspection data.

Advantages

- Automated inspection protocols reduce the necessity for hands-on involvement and decrease the duration spent on-site, thereby enhancing efficiency and quality.

- Drones are capable of approaching electrical equipment closely or utilizing high-resolution zoom lenses to obtain sharp, intricate visuals.

- Aerial inspections offer novel vantage points for inspecting critical components and facilitate the assessment of equipment condition through advanced thermal imaging analysis.

Solution

Portable Inspection

X8T: Compact portable substation inspection solution with multi-sensor/RTK EMI resistance, automated flight for confined spaces & safe, optimal shooting.

- Compact size (218×106×72.6mm folded) navigates confined subspaces, adhering to safety, enabling optimal shooting angles.

- Multi-sensor tech & RTK positioning ensure robust EMI resistance for stable, accurate substation inspections.

- Automated flight along pre-planned routes minimizes manual control, enhancing inspection efficiency.

- Lightweight (1190g) for easy deployment, supporting rapid readiness in substation environments.

Drone Platform

X8T

Triple-Camera Thermal Imaging Drone - 48MP | 30X Zoom | 640×480 IR | AI-Powered Night Vision | 47min Flight Time Read More

Learn MorePayload And Software

Portable Substation Inspection Solution: Navigate Confined Spaces with Precision—Introducing X8T

Substations are the critical hubs of electricity grids, yet their dense infrastructure, confined spaces, and high electromagnetic interference (EMI) pose unique challenges for inspection. Enter the X8T Portable Drone Solution—engineered to conquer these hurdles with compact agility, multi-sensor resilience, and automated precision, redefining how substation assets are monitored.

Compact Design: Maneuver Confined Spaces, Capture Optimal Angles

In substations, where every inch counts, size matters. The X8T’s foldable architecture (218×106×72.6mm folded, no propellers) and 1190g max takeoff weight make it the ultimate tool for navigating tight corridors between transformers, switchgear, and busbars. Its small footprint ensures compliance with safety regulations, maintaining safe distances from live equipment while its 3-axis gimbal articulates for unobstructed shooting angles—capturing high-resolution details of insulators, connectors, and cooling systems that ground-based inspections often miss.

Multi-Sensor & RTK: EMI-Resistant, Data You Can Trust

Substations are electromagnetic battlegrounds—ordinary drones falter, but X8T thrives. Equipped with multi-sensor technology (48MP visual camera, 640×480 infrared thermal sensor) and RTK positioning, it cuts through EMI to deliver stable, accurate data. The RTK module ensures ±0.1m vertical/±0.3m horizontal precision, even amid electrical noise, while the anti-jamming data link frequency-hopping technology (72 hops/sec) guarantees uninterrupted connectivity. Detect overheating components, corrosion, or oil leaks with confidence—no EMI interference, no data loss.

Automated Flight: Pre-Planned Routes, Minimal Manual Control

Human error and operator fatigue are risks in substation inspections. X8T eliminates these with automated flight along pre-planned routes: upload substation blueprints, set waypoints, and let the drone execute precise, repeatable missions. From checking breaker panels to scanning transformer banks, X8T flies autonomously, reducing manual control to a minimum. This not only boosts efficiency but ensures consistent data collection—critical for trend analysis and predictive maintenance.

Why X8T for Substation Inspection?

- Safety First: Compact size and automated flight minimize human exposure to high-voltage risks.

- 24/7 Readiness: Day/night imaging (via IR sensor) and 0–40°C operating range adapt to any substation schedule.

- Rapid Deployment: Unfold, power on, and launch in minutes—ideal for emergency fault checks or routine patrols.

Elevate Your Substation Inspection Today

Substations demand precision, resilience, and safety—X8T delivers all three. With its compact agility, EMI-resistant technology, and automated workflows, it transforms how you monitor critical assets, reducing downtime and enhancing grid reliability.

Ready to navigate confined spaces with confidence? Choose X8T—the portable solution that turns substation complexity into inspection simplicity.

X8T: Where compact power meets substation excellence.

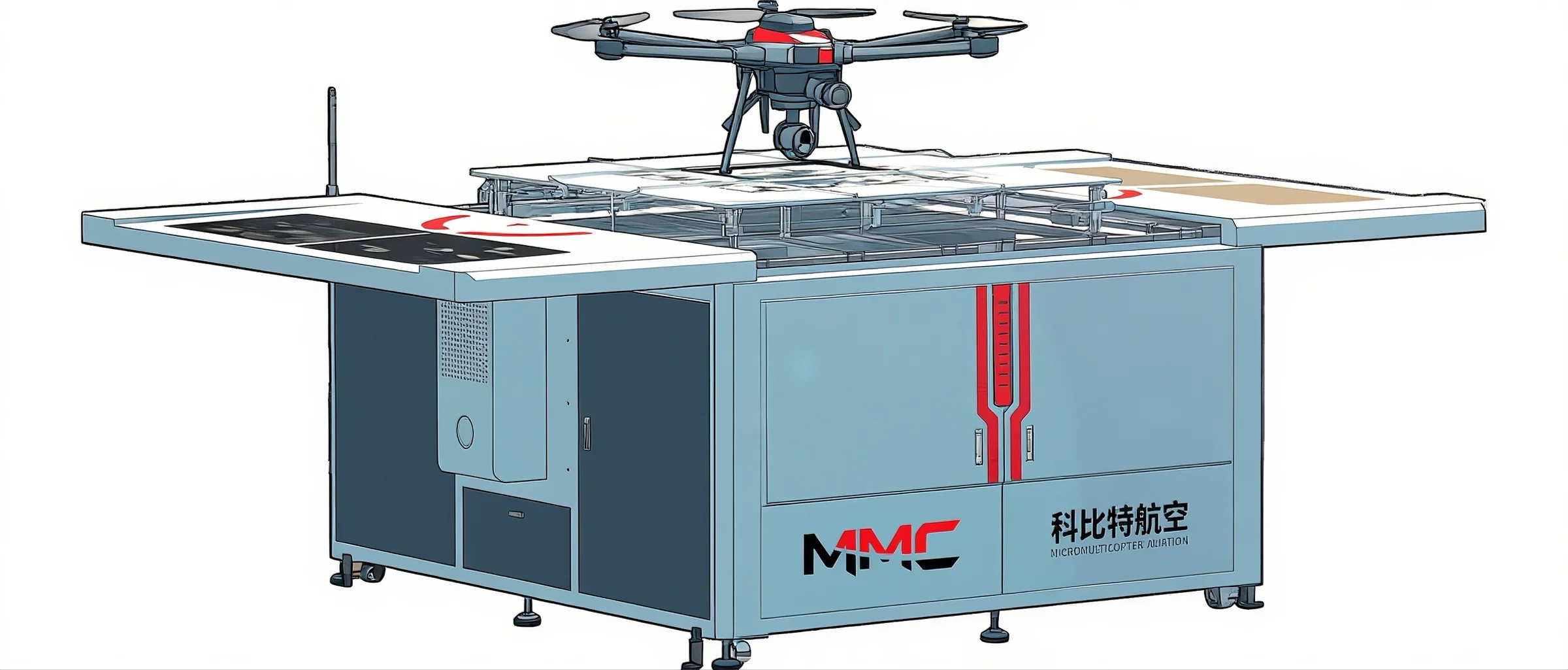

Automated Remote Inspection

Skylle Ⅱ: Automated remote substation inspection with dedicated hangar, enabling remote deployment, scheduled tasks & harsh weather resilience for reliable grid monitoring.

- Remote deployment reduces workload; centralized platform manages multiple docking stations easily.

- Scheduled tasks enable fully automated flight, data transmission & inspection processes.

- Designed for extreme cold/heat, wind, rain & dust, ensuring on-schedule, quality inspections.

- Centralized management enables remote control & real-time data monitoring for efficient grid oversight.

Drone Platform

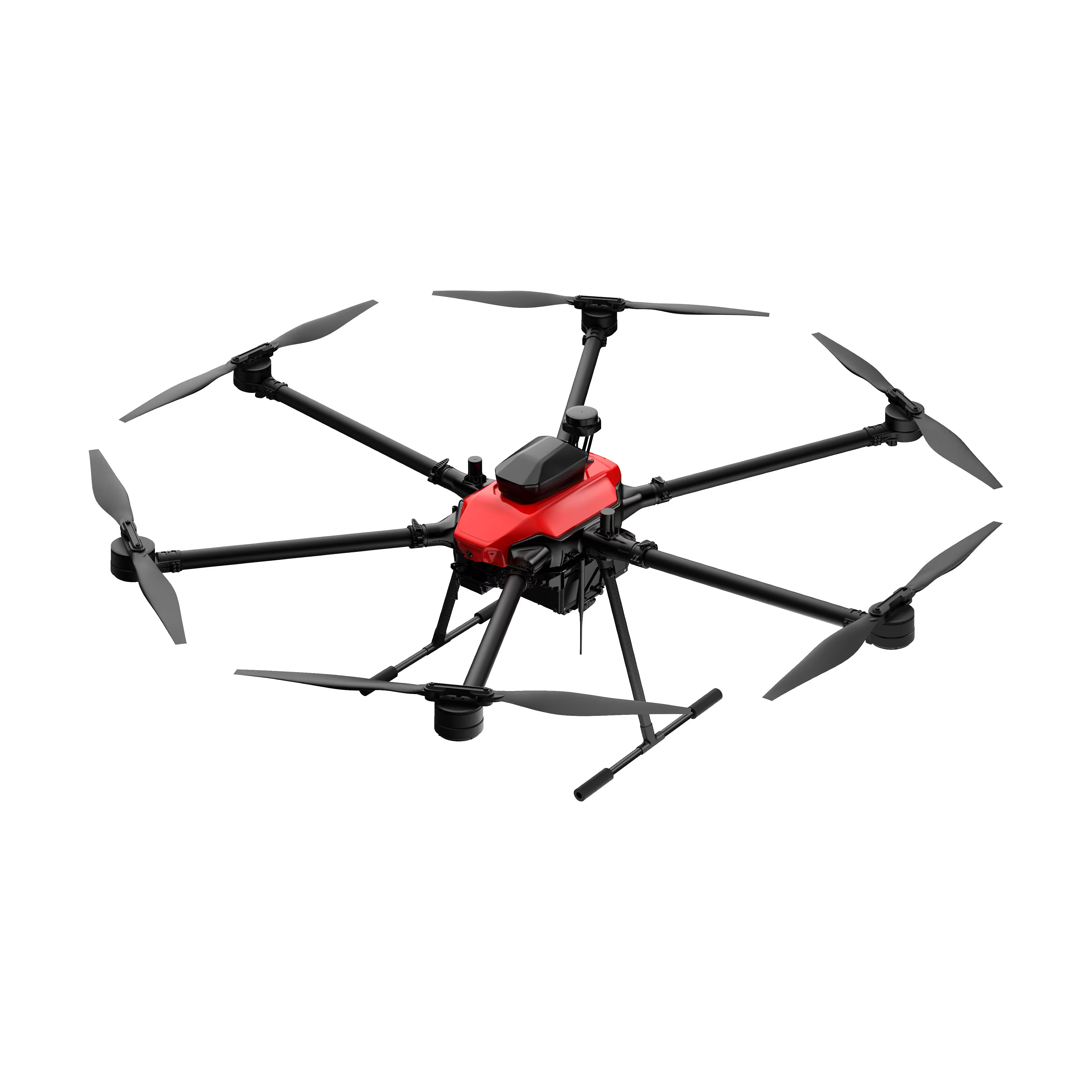

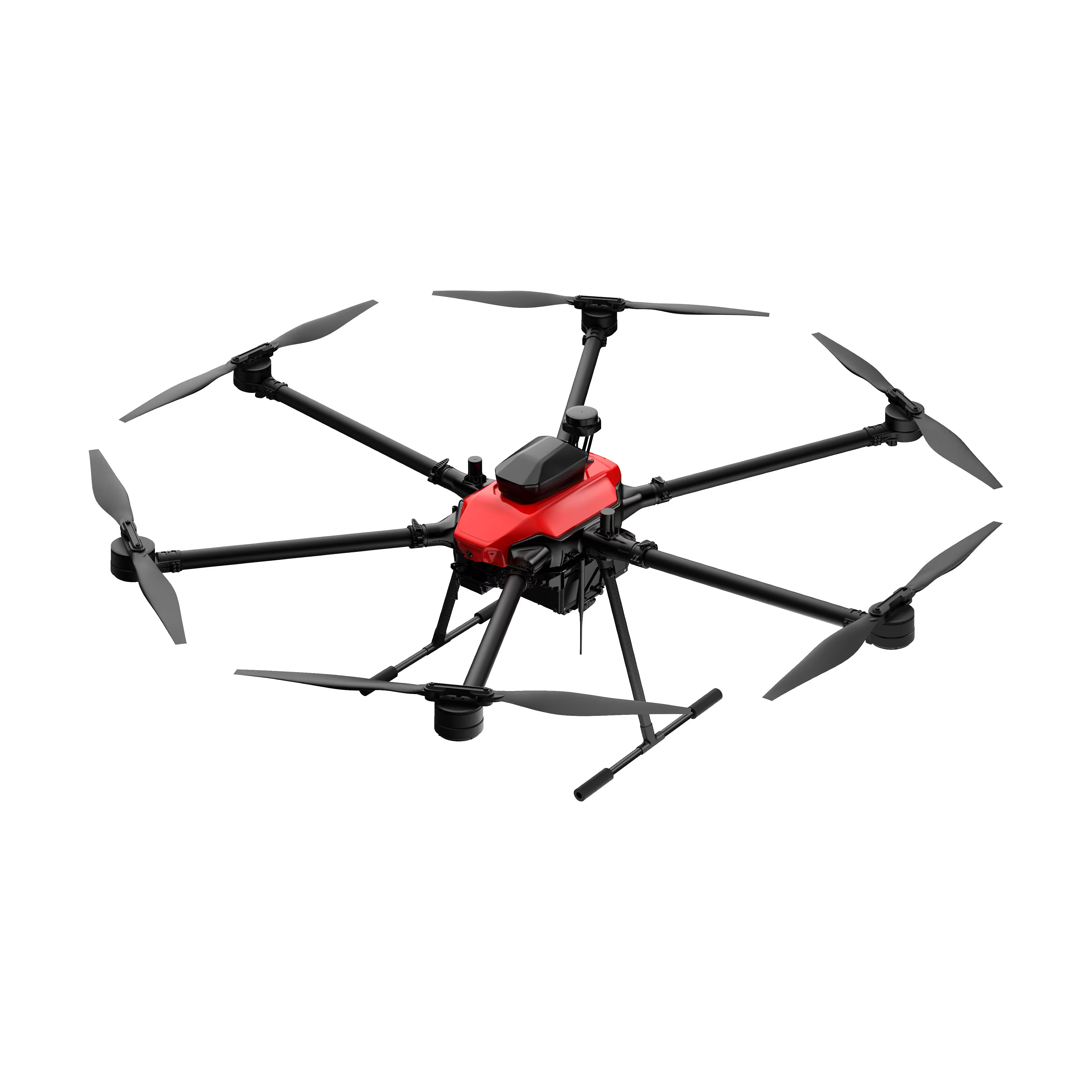

Skylle Ⅱ

Hexacopter Industrial Heavy-Lift Drone - 10kg Payload | 60min Flight Time | RTK cm-Level Positioning | IP54 Rated Read More

Learn MorePayload And Software

HT18R

Industrial-Grade 4-Sensor Payload Redefining Precision Inspection HT18R Find More Why Choose MMC HT18R? Multi-Sensor Integration Combines 48MP wide-angle/telephoto visible cameras, 640×512 thermal imager, and 2000m laser rangefinder, enabling comprehensive day-night observation and data collection in one payload. Read More

Learn More

HT10RW

A compact 4-in-1 camera payload (380g) designed for industrial drones, integrating multi-sensor capabilities to meet diverse mission requirements across day/night and complex environments. It is widely applicable in power inspection, oil pipeline monitoring, photovoltaic inspection, urban fire rescue, and forest fire prevention. Read More

Learn More

X4 Pro

MMC X4 Pro is a high-performance, multi-purpose aerial survey camera designed for 3D modeling and precision mapping. As a professional five-lens oblique photography system, it breaks through the limitations of traditional single-angle mapping cameras, providing an integrated, high-precision, and efficient aerial survey solution for various mapping scenarios. Read More

Learn More

X2C

A professional aerial survey camera designed for 3D modeling, capturing multi-angle spatial images to deliver realistic terrain/texture details for topographic, real estate, and architectural mapping. Read More

Learn MoreAutomated Remote Substation Inspection: Redefine Grid Reliability with Skylle Ⅱ & Dedicated Hangar

Substations are the lifelines of power grids, but traditional inspections—reliant on manual labor, weather-dependent schedules, and fragmented data—often fall short of efficiency and safety. Enter the Skylle Ⅱ Automated Remote Inspection Solution, pairing the advanced Skylle Ⅱ drone with its dedicated hangar to deliver 24/7, weather-resistant, and fully automated monitoring. From remote deployment to scheduled precision, this integrated system transforms substation inspection into a seamless, human-light operation.

Remote Deployment & Centralized Management: Reduce Workload, Amplify Control

Gone are the days of dispatching teams to remote substations or coordinating multiple on-site operators. The Skylle Ⅱ Solution empowers remote drone deployment via a user-friendly central management platform, enabling operators to control inspections from a single dashboard—no need for on-site presence. With support for centralized management of multiple docking stations, grid operators can monitor dozens of substations simultaneously: check hangar status, adjust missions, or review real-time data across sites—all with a few clicks. This drastically cuts personnel workload, eliminates travel time, and ensures consistent inspection quality across your entire network.

Scheduled Tasks: Fully Automated from Flight to Data Delivery

Automation is the cornerstone of the Skylle Ⅱ Solution. Set custom scheduled tasks (daily, weekly, or on-demand) via the platform, and let the system handle the rest: the hangar autonomously powers up Skylle Ⅱ, conducts pre-flight checks, and initiates takeoff. Skylle Ⅱ follows pre-planned routes with centimeter-level precision (via RTK positioning), capturing high-resolution visual and thermal data of transformers, insulators, and busbars. Post-flight, the drone lands automatically, docks with the hangar for charging, and streams data instantly to the cloud—where AI-powered analytics flag anomalies (e.g., overheating components, corrosion) and generate actionable reports. From takeoff to insight, it’s fully automated—no manual input required.

Harsh Weather Resilience: Inspect On-Schedule, Rain or Shine

Substations don’t shut down for bad weather—and neither does Skylle Ⅱ. Engineered for extreme conditions, the solution thrives where manual inspections falter:

- Temperature extremes: The hangar’s built-in thermal regulation system operates from -30°C to 60°C, ensuring Skylle Ⅱ stays mission-ready in scorching summers or freezing winters.

- Weatherproof design: With IP54-rated drone and IP65 hangar (dust-tight, water-resistant), it withstands heavy rain, 12m/s winds, and dust storms—no delays due to weather.

- All-weather reliability: Integrated weather sensors in the hangar auto-adjust missions (e.g., delaying takeoff during lightning) while ensuring data quality remains uncompromised.

Whether facing monsoons, sandstorms, or sub-zero temperatures, Skylle Ⅱ delivers on-time, high-quality inspections—keeping your grid resilient, rain or shine.

Why Skylle Ⅱ for Substation Inspection?

- Safety First: Remote operation eliminates human exposure to high voltages and hazardous environments.

- 24/7 Availability: Uninterrupted monitoring ensures critical issues are detected before they escalate into outages.

- Scalable Efficiency: Centralized management grows with your grid, supporting hundreds of substations from one platform.

Elevate Your Substation Inspection Today

The Skylle Ⅱ Automated Remote Inspection Solution isn’t just a tool—it’s a paradigm shift for power grid reliability. By combining remote deployment, full automation, and weather resilience, it turns substation inspection into a proactive, cost-effective, and risk-free process.

Ready to reduce workload, ensure on-schedule inspections, and future-proof your grid? Choose Skylle Ⅱ—where automation meets reliability, and every substation stays protected, no matter the conditions.

Skylle Ⅱ: Powering the future of automated substation inspection.

Multipurpose Drone Inspection

Skylle Ⅱ Multipurpose Drone: Substation Inspection solution with versatile payloads, long flight time, 3D mapping, HD zoom & laser rangefinder for efficiency.

- Versatile payloads (MMC HT18R/X4 Pro/X2C/HT10RW) for multi-mission inspection, enhancing operational efficiency.

- Long flight time (up to 50 mins) enables prolonged inspection in a single flight, reducing interruptions.

- High-density point cloud mapping creates precise 3D models for detailed inspection and asset analysis.

- HD zoom, laser rangefinder & intelligent re-shooting boost inspection accuracy and workflow efficiency.

Drone Platform

Skylle Ⅱ

Hexacopter Industrial Heavy-Lift Drone - 10kg Payload | 60min Flight Time | RTK cm-Level Positioning | IP54 Rated Read More

Learn More

Notuzi S

Professional-grade UAV designed for versatile industrial applications, catering to sectors such as power inspection, public security, energy, and firefighting. Read More

Learn MorePayload And Software

HT18R

Industrial-Grade 4-Sensor Payload Redefining Precision Inspection HT18R Find More Why Choose MMC HT18R? Multi-Sensor Integration Combines 48MP wide-angle/telephoto visible cameras, 640×512 thermal imager, and 2000m laser rangefinder, enabling comprehensive day-night observation and data collection in one payload. Read More

Learn More

X4 Pro

MMC X4 Pro is a high-performance, multi-purpose aerial survey camera designed for 3D modeling and precision mapping. As a professional five-lens oblique photography system, it breaks through the limitations of traditional single-angle mapping cameras, providing an integrated, high-precision, and efficient aerial survey solution for various mapping scenarios. Read More

Learn More

X2C

A professional aerial survey camera designed for 3D modeling, capturing multi-angle spatial images to deliver realistic terrain/texture details for topographic, real estate, and architectural mapping. Read More

Learn More

HT10RW

A compact 4-in-1 camera payload (380g) designed for industrial drones, integrating multi-sensor capabilities to meet diverse mission requirements across day/night and complex environments. It is widely applicable in power inspection, oil pipeline monitoring, photovoltaic inspection, urban fire rescue, and forest fire prevention. Read More

Learn MoreMultipurpose Drone Solution for Substation Inspection: Skylle Ⅱ & Versatile Payloads—Redefine Efficiency, Precision, and Insight

Substation Inspection is the backbone of grid reliability, requiring tools that adapt to complex assets, capture critical data, and streamline workflows. The Skylle Ⅱ Multipurpose Drone Solution is engineered to transform Substation Inspection by pairing the advanced Skylle Ⅱ drone with specialized payloads—MMC HT18R, X4 Pro, X2C, and HT10RW. From multi-payload versatility to extended flight time, high-density point cloud modeling, and intelligent imaging, this system elevates Substation Inspection into a data-rich, efficient process that leaves no detail overlooked.

Versatile Payloads: Powering Multi-Mission Substation Inspection

Substation Inspection demands flexibility to tackle diverse tasks—thermal diagnostics, high-res visual checks, 3D mapping, and precision measurements. Skylle Ⅱ delivers with interchangeable payloads tailored for Substation Inspection:

- HT18R: Thermal-visual hybrid payload with high-sensitivity IR sensors, detecting hotspots in transformers and busbars—critical for proactive Substation Inspection.

- X4 Pro: 48MP HD camera with 30x optical zoom, capturing insulator cracks or bolt looseness from safe distances, enhancing Substation Inspection detail.

- X2C: Lightweight LiDAR for high-density point cloud data, enabling 3D modeling of substation layouts—key for structural Substation Inspection.

- HT10RW: 10x zoom, 1200m laser rangefinder, and intelligent re-shooting, ensuring no missed details in Substation Inspection workflows.

One drone, multiple payloads—eliminating the need for separate tools and slashing Substation Inspection costs.

Extended Flight Time: Prolonged Substation Inspection in a Single Flight

Substation Inspection missions often span large areas, making frequent recharges a workflow bottleneck. Skylle Ⅱ solves this with long-endurance batteries, delivering up to 50 minutes of continuous flight (payload-dependent). This extended runtime lets operators cover entire substations in one flight—inspecting transformers, switchgear, and perimeter fencing without interruptions, maximizing Substation Inspection productivity.

High-Density Point Cloud Mapping: Precise Models for Substation Inspection

Accurate spatial data is vital for Substation Inspection, from asset dimensioning to structural health tracking. Skylle Ⅱ, paired with X2C LiDAR, generates high-density point clouds (200+ points/m²), creating precise 3D models of substation environments. These models enable:

- Clearance measurements between live components for safety compliance in Substation Inspection.

- Digital twin integration for virtual Substation Inspection and maintenance simulations.

- Tracking of structural changes over time, ensuring Substation Inspection captures even subtle shifts.

HD Zoom, Laser Rangefinder & Intelligent Re-Shooting: Precision in Substation Inspection

Substation Inspection relies on capturing clear, actionable data—even from afar. Skylle Ⅱ’s payloads excel here:

- HD Zoom: X4 Pro and HT10RW offer up to 30x optical zoom, bringing distant substation assets into sharp focus without compromising flight safety during Substation Inspection.

- Laser Rangefinder: HT10RW’s 1200m rangefinder provides real-time distance data, ensuring precise positioning for optimal Substation Inspection angles.

- Intelligent Re-Shooting: AI algorithms auto-flag blurry images, triggering re-captures mid-flight—eliminating post-inspection gaps and boosting Substation Inspection efficiency by 40%.

Elevate Your Substation Inspection Today

Skylle Ⅱ Multipurpose Drone Solution isn’t just a tool—it’s a Substation Inspection revolution. With versatile payloads, extended flight time, high-density mapping, and intelligent imaging, it transforms how you monitor, analyze, and maintain critical substation assets.

Ready to redefine Substation Inspection? Choose Skylle Ⅱ—where adaptability meets precision, and every flight drives smarter, more efficient Substation Inspection.

Skylle Ⅱ: The ultimate partner for next-level Substation Inspection.