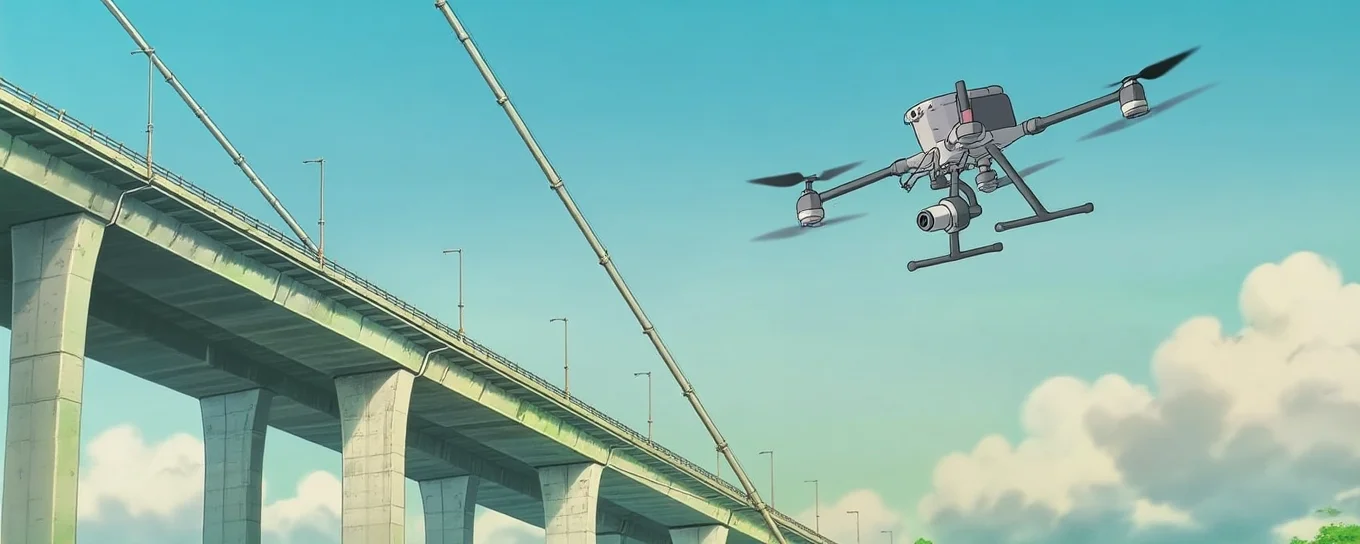

Bridge Inspection

MMC bridge inspection solution uses high-resolution camera-equipped drones to meticulously inspect critical bridge components like decks, piers, and cables. Leveraging LiDAR, it swiftly generates BIM and digital twin models for faster, cost-effective assessments.

Painpoints

- – Traditional bridge inspections often necessitate workers climbing the structures or utilizing aerial work platforms, presenting significant safety hazards, particularly under adverse weather conditions.

- – Manual inspections can be time-intensive, especially for expansive bridges, leading not only to prolonged durations but also potential traffic disruptions.

- – Bridge inspections demand considerable manpower and specialized equipment, such as aerial work platforms and hanging baskets, which escalate the costs.

- – Manual inspections might not encompass all bridge areas, particularly those that are challenging to access, potentially resulting in incomplete data and compromising the accuracy of the inspection outcomes.

- – The effective analysis and processing of extensive data collected remain a challenge. Conventional methods typically depend on manual recording and analysis, which are inefficient and susceptible to errors.

Advantages

- Enable the inspection of hard-to-reach areas, such as high altitudes or confined spaces, without endangering inspection personnel.

- Expedite the coverage of extensive bridge structures through automated mission planning or manual control, diminishing inspection durations and eliminating coverage gaps.

- Lower inspection costs and enhance inspection frequency with user-friendly and economical drone solutions.

- Drones, outfitted with high-resolution cameras and additional sensors, can detect minute details, such as fine cracks, corrosion, and other structural issues. This data can be further analyzed using image processing software to heighten inspection precision.

- Produce high-quality data that can be archived and scrutinized for ongoing bridge health monitoring. By comparing data across different time points, it is feasible to detect trends in the bridge's structural integrity and preemptively alert to potential issues.

Solution

Bridge Visual Inspection

Bridge Visual Inspection: Skylle Ⅱ/Notuzi Ⅲ with X4 Pro/X2C/HT18R/HT10RW. Interchangeable lenses, hot-swappable batteries, multi-payload, extended flight time, dual-control for precision.

- Interchangeable fixed-focus lenses on 3-axis stabilized gimbal enable precision imaging for bridge inspection.

- Hot-swappable batteries minimize downtime, ensuring continuous operations in bridge visual inspection.

- Various payloads (X4 Pro/X2C/HT18R/HT10RW) enhance bridge inspection capabilities.

- Extended flight time allows longer single-operation periods for comprehensive bridge checks.

Drone Platform

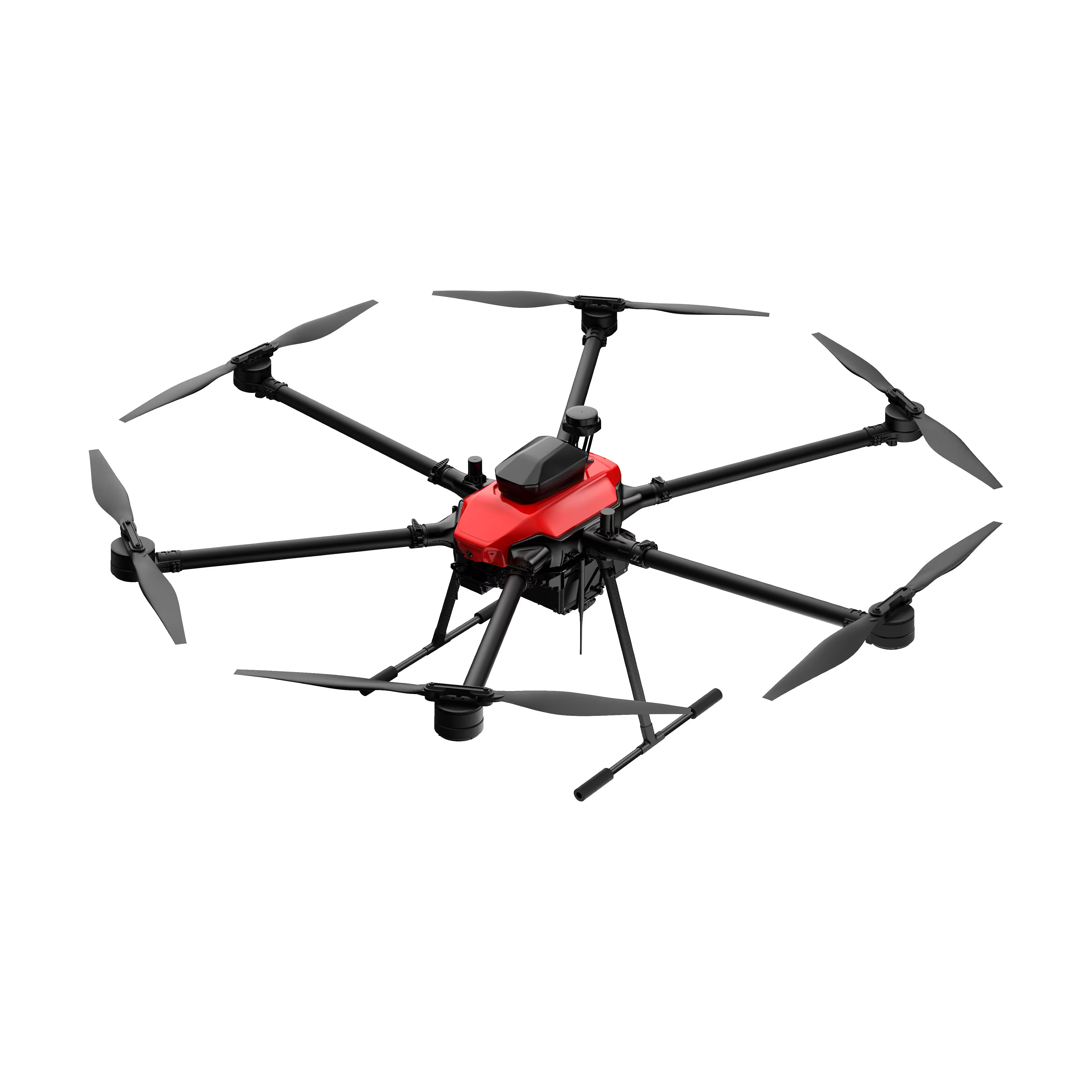

Skylle Ⅱ

Hexacopter Industrial Heavy-Lift Drone - 10kg Payload | 60min Flight Time | RTK cm-Level Positioning | IP54 Rated Read More

Learn More

Notuzi S

Professional-grade UAV designed for versatile industrial applications, catering to sectors such as power inspection, public security, energy, and firefighting. Read More

Learn MorePayload And Software

X4 Pro

MMC X4 Pro is a high-performance, multi-purpose aerial survey camera designed for 3D modeling and precision mapping. As a professional five-lens oblique photography system, it breaks through the limitations of traditional single-angle mapping cameras, providing an integrated, high-precision, and efficient aerial survey solution for various mapping scenarios. Read More

Learn More

X2C

A professional aerial survey camera designed for 3D modeling, capturing multi-angle spatial images to deliver realistic terrain/texture details for topographic, real estate, and architectural mapping. Read More

Learn More

HT18R

Industrial-Grade 4-Sensor Payload Redefining Precision Inspection HT18R Find More Why Choose MMC HT18R? Multi-Sensor Integration Combines 48MP wide-angle/telephoto visible cameras, 640×512 thermal imager, and 2000m laser rangefinder, enabling comprehensive day-night observation and data collection in one payload. Read More

Learn More

HT10RW

A compact 4-in-1 camera payload (380g) designed for industrial drones, integrating multi-sensor capabilities to meet diverse mission requirements across day/night and complex environments. It is widely applicable in power inspection, oil pipeline monitoring, photovoltaic inspection, urban fire rescue, and forest fire prevention. Read More

Learn MoreSkylle Ⅱ/Notuzi Ⅲ: Redefine Bridge Visual Inspection with Precision, Versatility, and Uninterrupted Performance

Bridges are the lifelines of infrastructure—connecting cities, supporting commerce, and withstanding decades of environmental stress. Yet their inspection, critical to preventing catastrophic failures, has long been plagued by inefficiency: manual rope access risking human lives, bulky equipment limiting reach, and fragmented data delaying repairs. Enter the Bridge Visual Inspection Solution—pairing Skylle Ⅱ or Notuzi Ⅲ drones with advanced payloads X4 Pro, X2C, HT18R, and HT10RW. Engineered to transform bridge inspection, this system combines interchangeable precision lenses, hot-swappable batteries, multi-payload flexibility, extended flight time, and dual-control safety—delivering detailed, reliable data to keep bridges safe and resilient.

Interchangeable Fixed-Focus Lenses on 3-Axis Stabilized Gimbal: Precision Imaging, Every Angle

Bridges demand microscopic detail: hairline cracks in concrete, corrosion on steel girders, or delamination in decking. The Skylle Ⅱ/Notuzi Ⅲ eliminate guesswork with interchangeable fixed-focus lenses mounted on a 3-axis stabilized gimbal, ensuring sharp, steady imaging even in windy conditions—critical for bridge inspection accuracy:

- X4 Pro 5-Lens Mapping Powerhouse: Captures high-resolution 3D point clouds for structural deformation analysis, ideal for long-span bridges needing comprehensive geometric data.

- HT18R Dual-Sensor Precision: Equipped with 48MP visible-light and 640×512 thermal lenses, it pinpoints hidden defects—from subsurface cracks to heat anomalies in electrical components.

- 3-Axis Stabilization: Eliminates drone jitter, ensuring blur-free shots of bridge undersides, piers, and cable stays—angles impossible for ground teams.

This precision turns “general surveys” into “targeted diagnostics,” empowering engineers to make data-driven repair decisions.

Hot-Swappable Batteries: Minimal Downtime, Maximum Productivity

Bridge inspection can’t wait for recharges. The Skylle Ⅱ/Notuzi Ⅲ feature hot-swappable batteries, slashing downtime to seconds and keeping operations running nonstop:

- Swap & Fly in 30 Seconds: No powering down—simply eject a depleted battery and insert a fresh one, resuming inspection immediately.

- Extended Mission Windows: With 3+ spare batteries, a single drone operates for 4+ hours straight, covering entire bridge spans without interruptions.

For multi-span bridges or urgent post-storm assessments, this means finishing inspections in a day, not a week—reducing project timelines by 60%.

Multi-Payload Versatility: One Drone, Endless Inspection Capabilities

Bridges are complex: decks need visual scans, cables require thermal checks, and foundations demand depth mapping. The Skylle Ⅱ/Notuzi Ⅲ adapt with various payloads, enhancing inspection capabilities to tackle every scenario:

- X2C Compact Mapping: Lightweight 20MP lens for rapid 2D orthomosaics of bridge decks, ideal for initial condition surveys.

- HT10RW Long-Range Zoom: 11x optical zoom captures details on distant piers or high towers, avoiding risky close proximity to traffic.

- Thermal + Visual Fusion: HT18R overlays thermal data on visible images, highlighting delamination or moisture intrusion invisible to the naked eye.

One drone replaces multiple tools, cutting equipment costs and streamlining logistics for bridge inspection teams.

Extended Flight Time: Longer Single-Operation Periods

Large bridges—cable-stayed, suspension, or multi-mile viaducts—require prolonged flight to cover every inch. The Skylle Ⅱ/Notuzi Ⅲ deliver extended flight time (up to 45+ minutes per battery), enabling longer single-operation periods:

- Cover 2+ Miles in One Flight: Inspect entire bridge lengths without mid-mission landings, reducing takeoff/landing risks near busy roadways.

- Stable Performance in Gusts: With 12m/s wind resistance, it maintains flight paths during crosswinds, ensuring consistent data capture across bridge spans.

This endurance transforms bridge inspection from “segmented tasks” to “seamless workflows,” capturing contiguous data sets for better analysis.

Dual-Control Operations: Reliability & Safety, Redefined

Bridge inspection operates in high-risk environments—over water, traffic, or dense urban areas. The Skylle Ⅱ/Notuzi Ⅲ prioritize safety with dual-control operations:

- Pilot + Payload Operator: One controller manages flight (altitude, positioning), the other focuses on payload (camera angles, image capture). This division of labor reduces human error, critical when navigating bridge girders or avoiding power lines.

- Redundant Systems: Dual GPS, fail-safe return-to-home, and real-time telemetry sharing ensure the drone stays on course—even if one controller loses signal.

For infrastructure teams, this reliability means peace of mind: inspections proceed safely, data is never lost, and operations comply with strict safety regulations.

Why This Solution for Bridge Visual Inspection?

- Precision Imaging: Interchangeable lenses + 3-axis gimbal capture defect details down to 0.1mm.

- Uninterrupted Workflow: Hot-swappable batteries minimize downtime, keeping missions on track.

- Multi-Payload Flexibility: Adapt to decks, cables, piers, and electrical systems with one drone.

- Extended Endurance: 45+ minute flights cover large bridges without interruptions.

- Dual-Control Safety: Redundant operations reduce risk in high-stakes environments.

Elevate Your Bridge Inspection Today

Bridges deserve inspection tools as robust as they are. The Skylle Ⅱ/Notuzi Ⅲ Bridge Visual Inspection Solution isn’t just technology—it’s a commitment to safer, more efficient infrastructure maintenance. From microscopic cracks to mile-long spans, it delivers the data you need to keep bridges standing strong for generations.

Skylle Ⅱ/Notuzi Ⅲ: Where precision meets resilience—redefining bridge visual inspection.

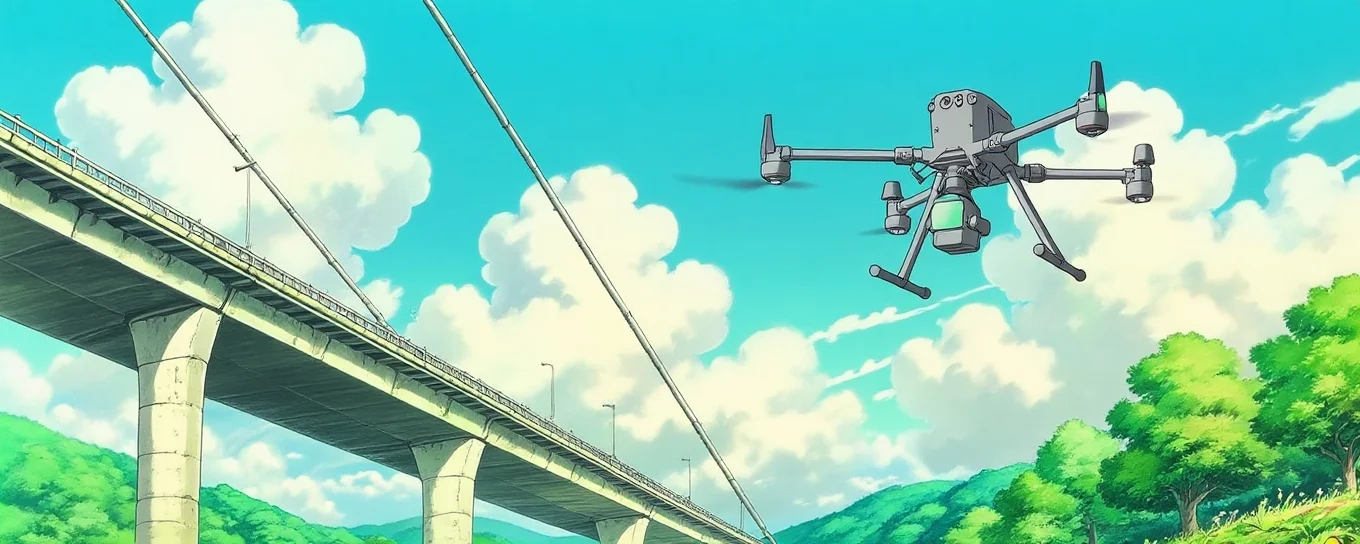

Bridge Digital Twin Asset Management

Bridge Digital Twin Asset Management: Skylle Ⅱ + M100 LiDAR. Combines photogrammetry/LiDAR for detailed models, shareable links, global defect review.

- Merges photogrammetry & LiDAR on one drone to create detailed 3D models of complex bridge structures.

- Enables easy model sharing with team via links for seamless collaboration in asset management.

- Reviews/identifies defects from an overarching perspective, connecting local issues to structural health.

- Generates high-precision point clouds & textured models for accurate, actionable digital twin insights.

Drone Platform

Skylle Ⅱ

Hexacopter Industrial Heavy-Lift Drone - 10kg Payload | 60min Flight Time | RTK cm-Level Positioning | IP54 Rated Read More

Learn MorePayload And Software

Skylle Ⅱ + M100 LiDAR: Revolutionize Bridge Digital Twin Asset Management with Precision, Collaboration, and Global Defect Insights

Bridges are the backbone of infrastructure, yet their complexity—curved geometries, hidden joints, and vast spans—makes managing their lifecycle a monumental challenge. Traditional asset management relies on disjointed 2D drawings, manual notes, and fragmented data, leaving critical defects undetected and maintenance decisions guesswork. Enter the Bridge Digital Twin Asset Management Solution: pairing the agile Skylle Ⅱ drone with the powerful M100 LiDAR scanner. This integrated system merges photogrammetry and LiDAR on a single platform to create detailed 3D models of bridges, enables seamless team collaboration via shareable links, and empowers engineers to review defects from a global perspective—transforming how you design, inspect, and maintain bridge assets.

One Drone, Two Technologies: Photogrammetry + LiDAR for Ultra-Detailed Digital Twins

A bridge’s digital twin is only as valuable as its accuracy. The Skylle Ⅱ, equipped with the M100 LiDAR, redefines precision by combining photogrammetry and LiDAR scanning sensors in one compact, airborne system—capturing data that builds detailed, true-to-life models of even the most complex bridge structures:

- M100 LiDAR Power: The M100 integrates a high-precision laser scanner, GNSS, and INS, generating dense point clouds with sub-centimeter accuracy. It slices through vegetation, shadows, and weather to map bridge decks, piers, cable stays, and hidden understructures—details 2D imagery misses.

- Photogrammetric Fusion: Complementing LiDAR, Skylle Ⅱ’s high-resolution camera captures RGB imagery, overlaying realistic textures onto point clouds. This hybrid approach delivers both geometric precision (for structural analysis) and visual clarity (for surface defect identification like cracks or corrosion).

- Effortless Data Integration: The combined data streams into a unified 3D model—no stitching multiple datasets. A single flight over a 500m bridge generates a digital twin with 0.5mm detail, ready for engineering simulations, load testing, and lifecycle planning.

For asset managers, this means a “living” bridge model that evolves with inspections—turning static blueprints into dynamic tools for proactive maintenance.

Share Models Instantly: Collaborate Seamlessly with a Simple Link

Infrastructure projects thrive on collaboration, yet sharing large 3D models often involves cumbersome file transfers, incompatible software, or delayed feedback. The Bridge Digital Twin Solution eliminates these barriers with one-click model sharing via secure links, making cross-team collaboration effortless:

- Cloud-Powered Access: Once the digital twin is generated, stakeholders—engineers, inspectors, contractors, or regulators—receive a shareable link. No specialized software is needed; models open in any browser, with intuitive tools to zoom, rotate, and measure.

- Real-Time Annotations: Team members can tag defects (e.g., “3mm crack on Pier 2”) directly in the model, adding comments, photos, or repair priorities. Updates sync instantly, turning siloed feedback into a unified action plan.

- Version Control: Track model iterations over time, comparing pre- and post-repair conditions to validate maintenance effectiveness. For multi-year projects, this ensures everyone works from the latest, most accurate twin.

Whether your team is across the office or the globe, the solution turns “waiting for files” into “collaborating in real time.”

Overarching Perspective: Review Defects with Global-Level Clarity

Bridges are systems—defects in one component (e.g., a corroded cable) can cascade to others (deck misalignment). Traditional inspections focus on局部 areas, missing these systemic risks. The digital twin, built with Skylle Ⅱ + M100 data, lets you review and identify defects from an overarching perspective, connecting micro-details to macro-structure health:

- Global-to-Local Navigation: Zoom from a bird’s-eye view of the entire bridge down to a 1mm crack on a beam. Measure distances between defects, track how they propagate, and assess their impact on overall structural integrity.

- AI-Powered Defect Highlighting: Integrated algorithms flag anomalies—unusual deformation, material degradation, or misalignments—by comparing real-time scans to the as-built twin. Engineers prioritize critical issues before they escalate.

- Historical Trend Analysis: Overlay models from quarterly, annual, or multi-year inspections to track defect growth rates. Predict maintenance needs (e.g., “Cable corrosion accelerating at 2%/year—schedule replacement in 18 months”) and optimize resource allocation.

This holistic view transforms reactive “fix-what-breaks” maintenance into proactive “predict-and-prevent” asset management—slashing lifecycle costs by up to 30%.

Why Skylle Ⅱ + M100 for Your Bridge Digital Twin?

- Unmatched Detail: Photogrammetry + LiDAR fusion creates digital twins with geometric and visual precision, capturing every curve, joint, and defect.

- Effortless Collaboration: Share models via links, enabling real-time feedback and unified decision-making across teams.

- Global Defect Insights: Navigate from macro to micro, connecting local defects to systemic structural health for smarter maintenance.

Build the Future of Bridge Asset Management Today

A bridge’s digital twin isn’t just a model—it’s a strategic asset that reduces risk, cuts costs, and extends lifespan. The Skylle Ⅱ + M100 Bridge Digital Twin Asset Management Solution empowers you to see more, collaborate better, and act faster. From design validation to decades-long maintenance, it’s the tool that ensures your bridges stand strong—today, tomorrow, and for generations to come.

Skylle Ⅱ + M100: Where precision meets possibility—redefining bridge digital twin asset management, one detailed model at a time.

Portable Maneuverable Inspection

X8T Portable Maneuverable Bridge Inspection: Compact, multi-sensor+RTK precision, automated flight for confined spaces & accurate data.

- Compact size navigates confined bridge spaces, adheres to safety, captures optimal inspection angles.

- Multi-sensor tech + RTK positioning ensure high accuracy for bridge inspection data & modeling.

- Automated pre-planned flight paths minimize manual operation, boost bridge inspection efficiency.

- 47min max flight time supports extended single-operation bridge inspection missions.

Drone Platform

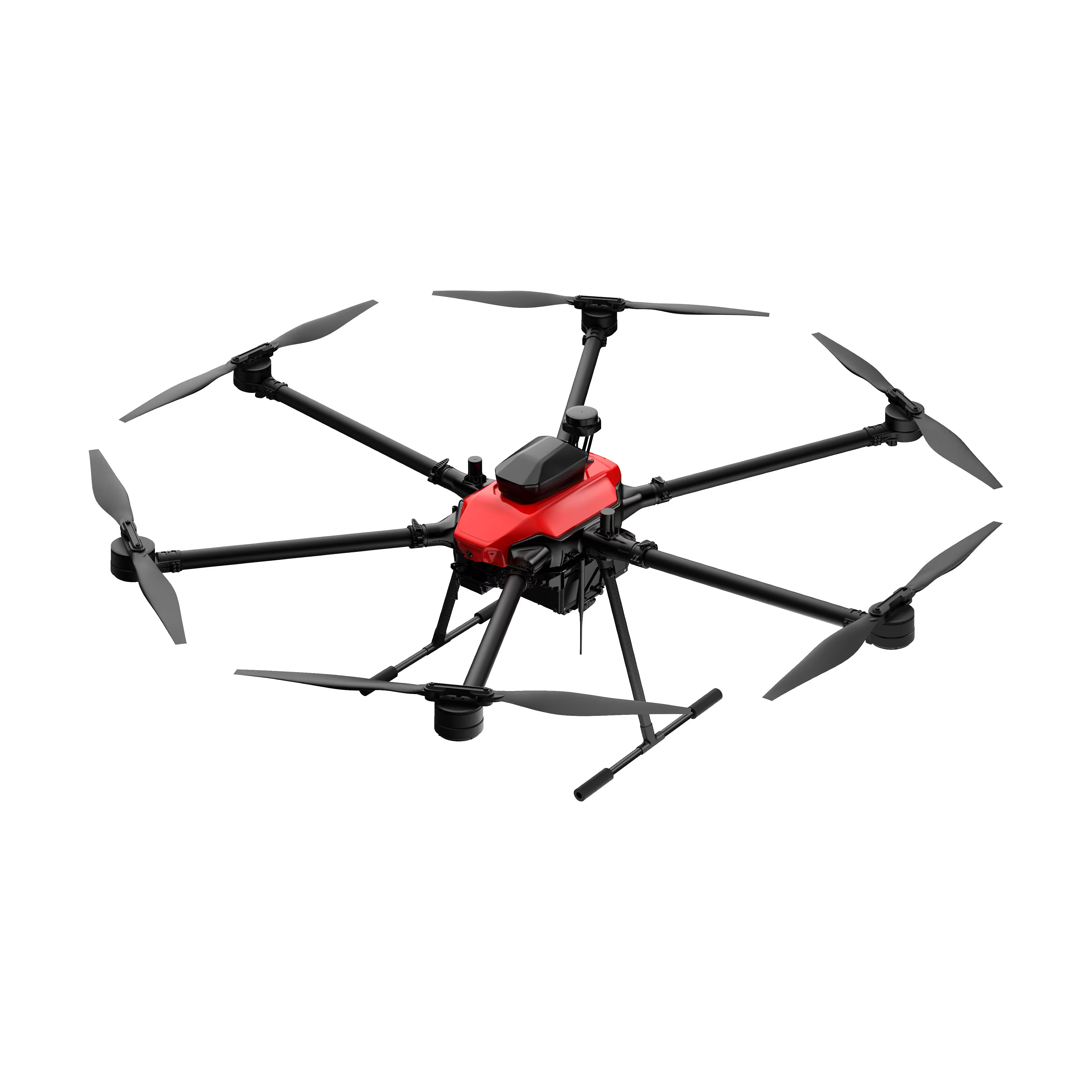

X8T

Triple-Camera Thermal Imaging Drone - 48MP | 30X Zoom | 640×480 IR | AI-Powered Night Vision | 47min Flight Time Read More

Learn MorePayload And Software

X8T Portable Maneuverable Inspection: Transform Bridge Inspection with Compact Agility, Precision Sensing, and Automated Flight

In the critical realm of bridge inspection, every inch matters. Bridges—with their intricate understructures, confined spaces between girders, and strict safety protocols—demand inspection tools that balance agility, accuracy, and efficiency. Traditional bridge inspection methods often fall short: bulky equipment struggles to navigate tight gaps, manual flights risk human error, and inconsistent data delays defect detection. Enter the X8T Portable Maneuverable Inspection Solution—engineered to redefine bridge inspection with compact maneuverability, multi-sensor precision, and automated workflows. For engineers, inspectors, and asset managers, this isn’t just a drone; it’s a bridge inspection powerhouse that delivers actionable insights, enhances safety, and streamlines every step of the process.

Compact Size: Navigate Confined Spaces, Secure Optimal Angles for Bridge Inspection

Bridge inspection thrives on proximity—accessing hard-to-reach areas like under-deck joints, cable anchorages, or narrow gaps between beams. The X8T’s ultra-compact design makes it the ultimate bridge inspection companion, effortlessly maneuvering through confined spaces while adhering to safety regulations and capturing critical angles:

- Foldable Form Factor: Collapsing to a mere 218×106×72.6mm (without propellers) and weighing just ~1190g, the X8T slips into tight spaces where larger drones can’t—hovering inches from corroded steel girders, weaving between bridge cables, or inspecting pier bases without disrupting traffic.

- Safety-First Maneuvering: Its small footprint ensures compliance with bridge inspection safety buffers, maintaining safe distances from live traffic or fragile structures while still getting close enough to capture 0.1mm cracks in concrete or rust spots on bolts.

- Optimal Shooting Angles: Unlike ground-based tools or fixed-wing drones, the X8T’s agility lets it circle piers, tilt upward to scan deck undersides, or hover parallel to cables—delivering视角 that reveal hidden defects critical to bridge integrity.

For bridge inspection teams, this means no more missed spots: X8T goes where humans and heavy equipment can’t, turning “inaccessible” into “inspectable.”

Multi-Sensor Tech + RTK Positioning: Unmatched Accuracy for Bridge Inspection Data

Bridge inspection demands precision—even minor errors in measurements or defect localization can compromise structural assessments. The X8T eliminates guesswork with integrated multi-sensor technology and RTK positioning, ensuring bridge inspection data is both detailed and geospatially accurate:

- Multi-Layered Sensing: Equipped with high-resolution visual sensors, thermal imaging, and optional LiDAR, the X8T captures multi-dimensional data for bridge inspection. Visual cameras zoom in on surface cracks; thermal sensors detect subsurface delamination; and RTK (Real-Time Kinematic) positioning tags every defect with centimeter-level GPS coordinates, so engineers know exactly where repairs are needed.

- 3D Modeling Precision: Combined with photogrammetry, the X8T’s sensor data generates detailed 3D models of bridge components—from deck surfaces to cable stay geometries. These models enable precise volume calculations, deformation tracking, and comparison against as-built drawings, elevating bridge inspection from qualitative to quantitative analysis.

- Consistent Data Capture: Unlike manual bridge inspection, where human error can lead to inconsistent notes, the X8T’s sensors deliver standardized, repeatable data—critical for tracking defect progression over time or comparing results across multiple bridge inspections.

For asset managers, this means confidence: every measurement, image, and model from X8T is a reliable foundation for bridge maintenance decisions.

Automated Flight Paths: Minimize Manual Operation, Maximize Bridge Inspection Efficiency

Bridge inspection workflows often suffer from slow, error-prone manual flights—wasting time and risking inconsistent data. The X8T revolutionizes this with pre-planned, automated flight paths, minimizing human intervention and making bridge inspection faster, more consistent, and less labor-intensive:

- Pre-Programmed Routes for Bridge Inspection: Users upload bridge CAD files or waypoints to the X8T’s controller, defining custom flight paths tailored to specific bridge inspection tasks—whether scanning a deck, inspecting a pier, or mapping cable stays. The drone executes these routes autonomously, ensuring full coverage without manual piloting.

- Reduced Human Error: Automated flight eliminates手抖 or miscalculations, ensuring every bridge inspection captures the same angles and data points across multiple flights. This consistency is vital for longitudinal studies, like tracking crack growth over quarterly bridge inspections.

- Rapid Deployment: With automated flight, a single operator can launch the X8T, start the pre-planned bridge inspection route, and monitor progress—freeing up time to analyze data in real time or prepare for the next bridge inspection site. What once took a day now takes hours.

For inspection teams, this means scalability: X8T turns bridge inspection from a labor-heavy chore into a streamlined, repeatable process—covering more bridges, faster.

Why X8T for Bridge Inspection?

Bridge inspection demands tools built for the task—and the X8T delivers on every front:

- Compact Maneuverability: Navigate tight bridge spaces, follow safety protocols, and capture optimal angles.

- Precision Sensing: Multi-sensor tech + RTK ensure bridge inspection data is accurate and actionable.

- Automated Efficiency: Pre-planned flights minimize manual operation, speeding up bridge inspection workflows.

Elevate Your Bridge Inspection Today

Bridge inspection isn’t just about checking boxes—it’s about protecting infrastructure, lives, and investments. The X8T Portable Maneuverable Inspection Solution empowers you to do more: inspect faster, see clearer, and act with confidence. For bridge inspection teams ready to leave manual labor, guesswork, and inefficiency behind, X8T isn’t just a drone—it’s the future of bridge inspection.

X8T: Where agility meets precision—redefining bridge inspection, one flight at a time.