Oil and Gas

MMC oil and gas inspection solution revolutionizes operations by enhancing efficiency across inspection, asset management, and construction monitoring. Equipped with high-resolution cameras and thermal sensors, drones provide accurate, real-time data while minimizing the need for manual checks in hazardous environments. This reduces operational costs, improves safety, and supports smarter, tech-driven decision-making in oil and gas infrastructure.

MMC Drone Solutions for Oil and Gas

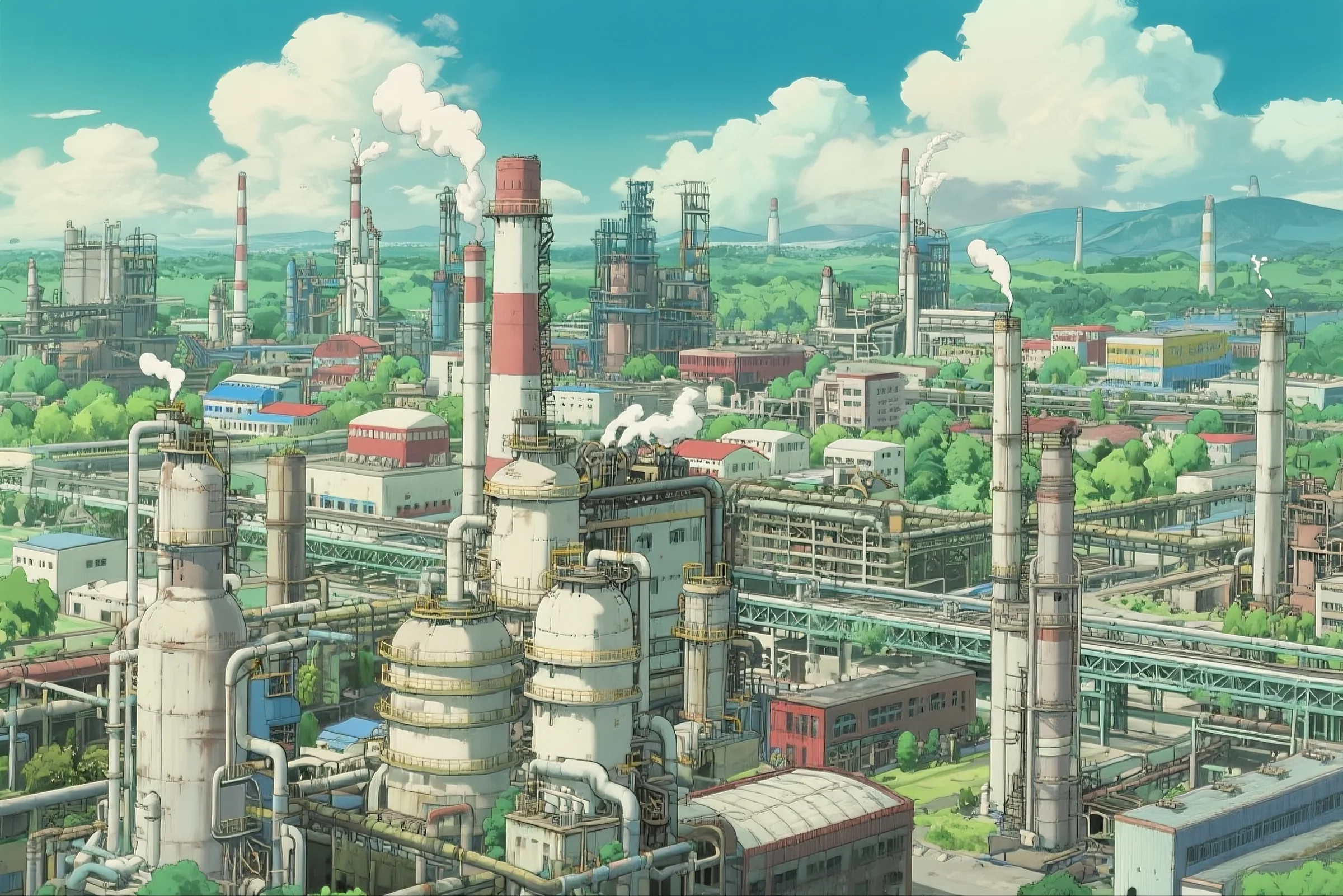

Facility Inspection

MMC facility inspection solution streamlines daily checks of pumping units by overcoming access challenges with aerial visibility. Equipped with visual and thermal cameras, drones capture detailed multi-angle imagery to detect issues like overheating, oil leaks, and loose components.

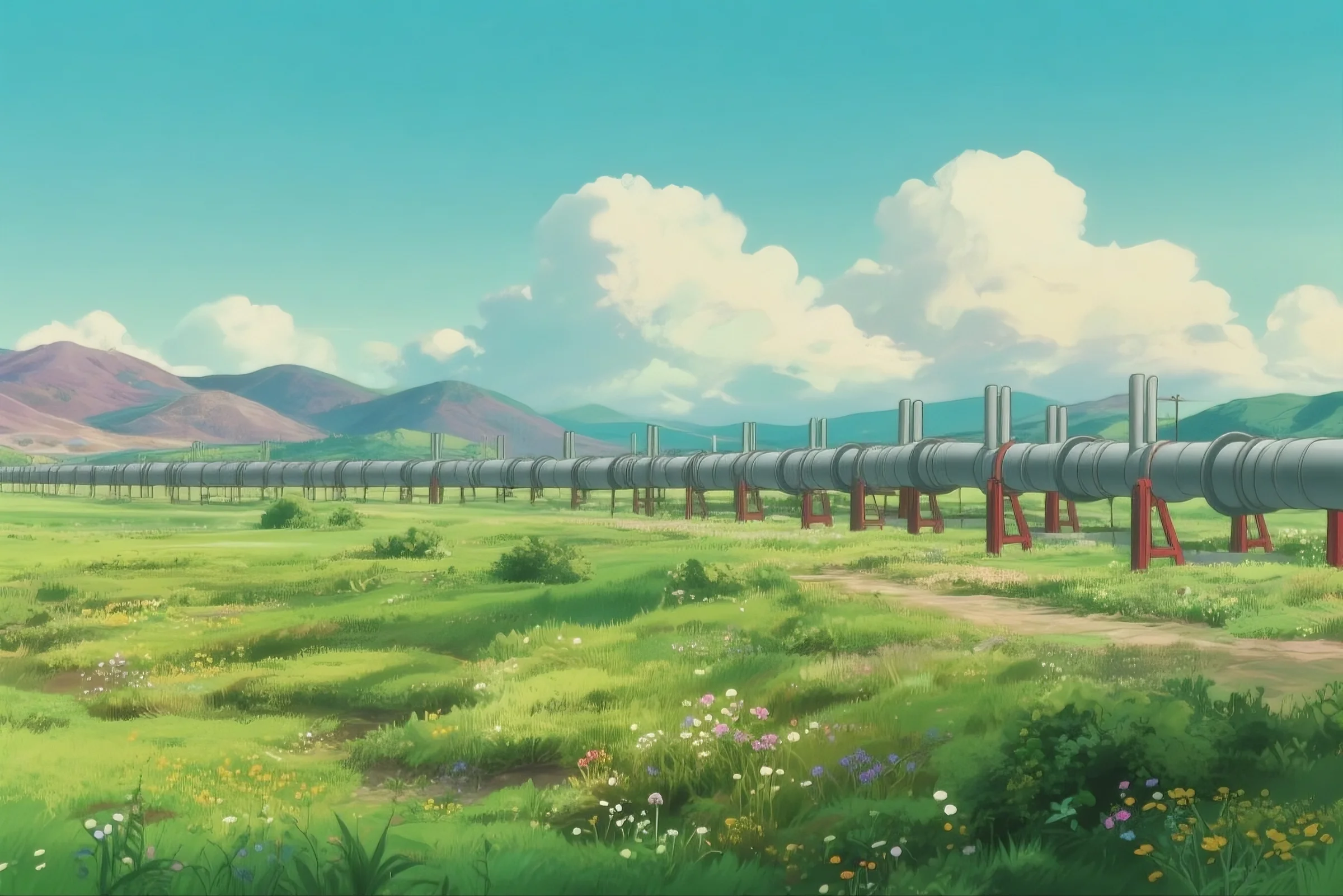

Pipeline Inspection

MMC pipeline inspection solution offers a safe, efficient method for monitoring oil field pipelines across remote and rugged terrains. Equipped with visible light and thermal cameras, drones perform automated inspections to detect leaks, temperature anomalies, and structural issues.

Traditional Challenges for Facility Inspection

- The structure's complexity, with many blind spots, makes it challenging for inspection teams to conduct thorough inspections.

- Oil fields are often hazardous and vast, requiring frequent inspections. This results in a significant allocation of human resources to inspection tasks.

- Traditional inspection methods cannot be easily digitized, archived, or traced.

- Oil field operations are subject to stringent regulations and must comply with local, state, and federal standards.

How Drones Aid Facility Inspection

- Close-range, multi-angle inspections effectively address the issue of blind spots and dead corners, enabling the identification of potential problems.

- Drones can cover large areas, reducing the need for manual labor on foot and ensuring the safety of personnel and production.

- Inspection data can be easily stored and tracked over time, leading to improvements in asset management and preventive maintenance efforts.

- Drone data can be utilized to monitor and ensure operational compliance, as well as to generate supporting documentation and reports for compliance teams.

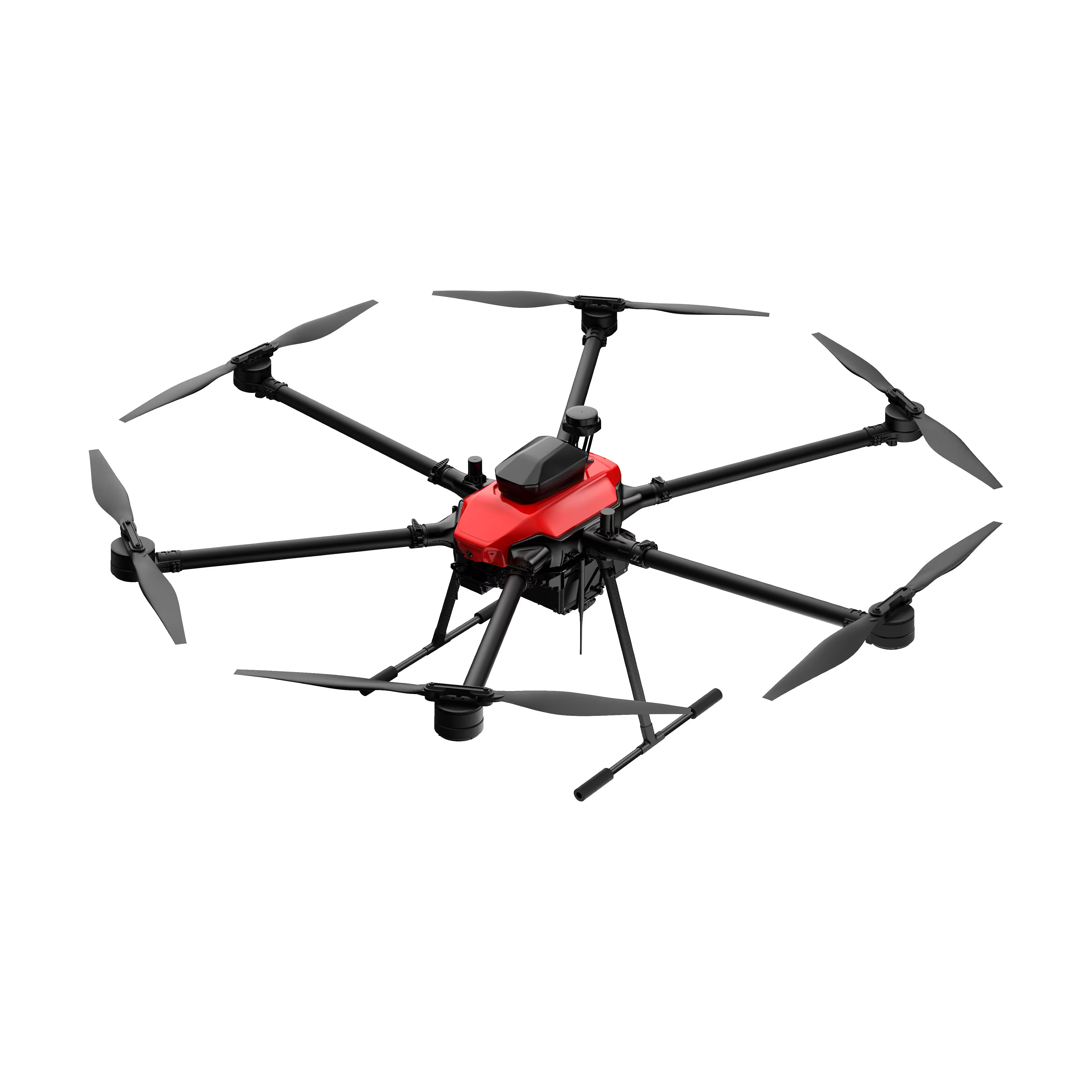

Related Products

Traditional Challenges for Pipeline Inspection

- Pipelines often stretch across long distances in challenging terrains, rendering manual inspections hazardous and expensive.

- Corrosion is a significant concern for pipelines, necessitating regular inspections to assess the structural integrity and detect potential leaks.

- Traditional inspection methods struggle to maintain accurate documentation of changes due to external or environmental factors.

How Drones Aid Pipeline Inspection

- Drones can swiftly cover extensive pipeline corridors, enhancing inspection efficiency without subjecting personnel to unnecessary risks.

- Increase the frequency and quality of inspections with pre-planned and repeatable drone-based inspections.

- Digitize your inspection records with drone data that is easily stored and shared.